Green concrete, TikTok and smart beer brewing technology are among the innovative solutions being explored by manufacturers to support Australia’s net zero by 2050 target, according to discussions at the Western Sydney Manufacturers Forum held last week.

The forum, hosted by the NSW Smart Sensing Network and the NSW Decarbonisation Innovation Hub at Penrith Panthers, brought together over 30 experts from universities, industry, and government to examine how the sector—responsible for 10 per cent of the nation’s carbon emissions—can play a critical role in decarbonisation.

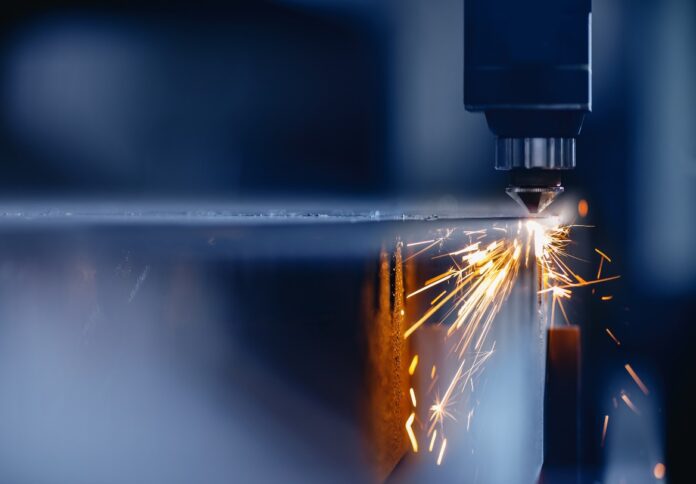

Speakers presented a range of technologies already delivering real-world impact, including carbon-tracking sensors, automation tools, and more sustainable materials for construction.

One major area of opportunity highlighted was the reduction of emissions from concrete production, which accounts for around eight percent of global carbon emissions—more than aviation and shipping combined.

Professor Olivia Mirza from Western Sydney University spoke about the early hesitation surrounding ‘green concrete’, a product made using recycled waste materials.

The material was used in the Parramatta Light Rail project despite its initial cost premium. “The initial cost for building (the Light Rail using green concrete) was, let’s say 10 or 12 percent higher, but then if you do the cost benefit analysis—less maintenance—it ended up saving 25 percent,” she said.

Alongside technical innovations, forum attendees also emphasised the need for better communication tools to raise awareness around sustainability—suggesting platforms like TikTok as an effective way to reach younger and trade-focused audiences about low-carbon alternatives in building and construction.

Dr Martin Ams, a product engineer at Macquarie University, presented a new generation of optical fibre sensors designed to monitor corrosion in concrete wastewater infrastructure.

“Over time, concrete can actually capture and remove CO2 directly from the atmosphere through a process known as carbonation,” he explained.

“If you have concrete structures that are absorbing CO2 from your atmosphere, you want them to last long so you can keep absorbing this CO2.”

Digital transformation was another key theme, with Dr Victor Hernandez Moreno from the UTS Centre for Advanced Manufacturing detailing how ‘digital twin’ technology can support smarter production decisions.

His team operates two synchronised beer brewing facilities in Sydney and Germany that share data in real time.

Keynote speaker Matt Kean, Chair of the Federal Government’s Climate Change Authority, said Western Sydney’s advanced manufacturing base is well-positioned to lead Australia’s net zero journey.

“The (Authority’s) Sector Pathways Review revealed that Australia has a great shot at crafting the products, goods, and services that will be in high demand,” he said.

“As the world shifts to net zero, we must be prepared to back our entrepreneurs and innovators and remove policy and regulatory barriers that inhibit progress.”

He noted that green hydrogen, ammonia, and metals will be essential in reshaping Australian industry and are expected to attract global demand.

“Importantly, they’re going to be in hot demand, not just domestically, but right across the globe,” Kean added.

Manuel Weirich, principal advisor at the NSW Net Zero Commission, said light industries like manufacturing and small-scale processing—which collectively contribute 45 per cent of NSW’s industrial emissions—represent a significant opportunity for emissions reductions through electrification and efficiency improvements.

The event aimed to help manufacturers navigate evolving emissions reporting requirements while demonstrating how sustainability can deliver both environmental and commercial benefits.