Scientists from Australia and the US are one step closer to finding out how to make organs such as lungs, livers and hearts using 3D printing.

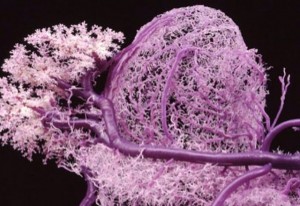

According to the news release by the University of Sydney, research teams from the University of Sydney, Harvard, Stanford and MIT have managed to manufacture a complex network of artificial blood vessels that imitate the circulatory system of the human body.

“Thousands of people die each year due to a lack of organs for transplantation. Many more are subjected to the surgical removal of tissues and organs due to cancer, or they’re involved in accidents with large fractures and injuries. Imagine being able to walk into a hospital and have a full organ printed — or bio-printed, as we call it — with all the cells, proteins and blood vessels in the right place, simply by pushing the ‘print’ button in your computer screen,” said Dr Luiz Bertassoni, study lead author and researcher at University of Sydney.

“We are still far away from that, but our research is addressing exactly that. Our finding is an important new step towards achieving these goals. At the moment, we are pretty much printing ‘prototypes’ that, as we improve, will eventually be used to change the way we treat patients worldwide.”

The biggest challenge on the path to this goal was finding out how to print the parts of the circulatory system. Since cells need unobstructed access to oxygen and nutrients, as well as a waste disposal system, a completely functional system is key to engineering tissues and organs.

“One of the greatest challenges to the engineering of large tissues and organs is growing a network of blood vessels and capillaries. Cells die without an adequate blood supply because blood supplies oxygen that’s necessary for cells to grow and perform a range of functions in the body,” said Dr Bertassoni.

“To illustrate the scale and complexity of the bio-engineering challenge we face, consider that every cell in the body is just a hair’s width from a supply of oxygenated blood. Replicating the complexity of these networks has been a stumbling block preventing tissue engineering from becoming a real world clinical application.”

After fabricating numerous tiny fibres that served as a scaffold for artificial blood vessels using a bio-printer, they covered the scaffold with a cell-rich, solidified protein-based material that has been exposed to light.

Once the fibres were removed, all that was left was the network of tiny channels coated with human endothelial cells “which self-organised to form stable blood capillaries in less than a week.”

“While recreating little parts of tissues in the lab is something that we have already been able to do, the possibility of printing three-dimensional tissues with functional blood capillaries in the blink of an eye is a game changer,” said Dr Bertassoni.

“Of course, simplified regenerative materials have long been available, but true regeneration of complex and functional organs is what doctors really want and patients really need, and this is the objective of our work.”

Watch bio-printing in action below.