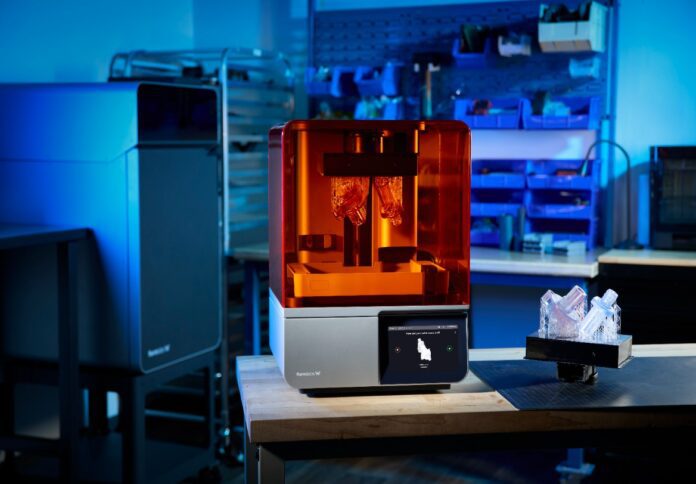

Global 3D printing giant Formlabs has introduced new flagship resin 3D printers, Form 4 and Form 4B.

In a news release, Formlabs said the 3D printers incorporate its innovative Low Force Display (LFD) print engine, enhancements to the company’s renowned resin collection, streamlined automated post-processing, and an enhanced user interface.

With Form 4 boasting print speeds up to five times faster than its predecessor, Formlabs said it is poised to enhance productivity for professionals across various industries, from product design and engineering to healthcare.

Max Lobovsky, CEO and co-founder of Formlabs, hailed Form 4 as a game-changer, not only for the company and its clients but also for the entire 3D printing landscape.

Lobovsky emphasised that Form 4 represents a culmination of over a decade of innovation and customer feedback, resulting in the most advanced SLA printer the company has ever produced.

“We’ve built on the strength and insights gathered from more than 130,000 printers on the market and over 300 million parts printed to deliver the Form 4, our best SLA printer ever. Its reliability and new level of speed will transform how our customers develop new products,” he noted.

Highlights of Form 4 include blazing fast print speeds due to its LFD print engine, ensuring industry-leading print success rates.

Moreover, the company said Form 4 is designed to be intuitive for users of all skill levels, with automated resin handling, instant material changes, and quick release build platform technology.

It offers a 40 per cent lower cost per part compared to its predecessor, making it not only more efficient but also more cost-effective.

Mark Honschke, Additive Prototyping Lead at Microsoft, and Bruno Alves, Development Engineer AM/IM at Ford Motor Company, both lauded the Form 4 for its speed, versatility, and impact on their respective industries.

Honschke highlighted its ability to produce high-performance parts with fast print times, while Alves emphasised its role in driving efficiency in product development at Ford.

In addition to the Form 4 printers, Formlabs has introduced six new resins to its extensive resin library, including reformulated General Purpose Resins and specialised options like Fast Model Resin and Precision Model Resin, catering to a wide range of applications.

Furthermore, Form 4B, tailored for healthcare professionals, offers compatibility with a variety of biocompatible materials, expanding its utility in the dental and medical fields.