Jaguar Land Rover (JLR) has implemented Ericsson Private 5G at its Solihull manufacturing plant, aiming to enhance industrial connectivity and support its digital transformation efforts.

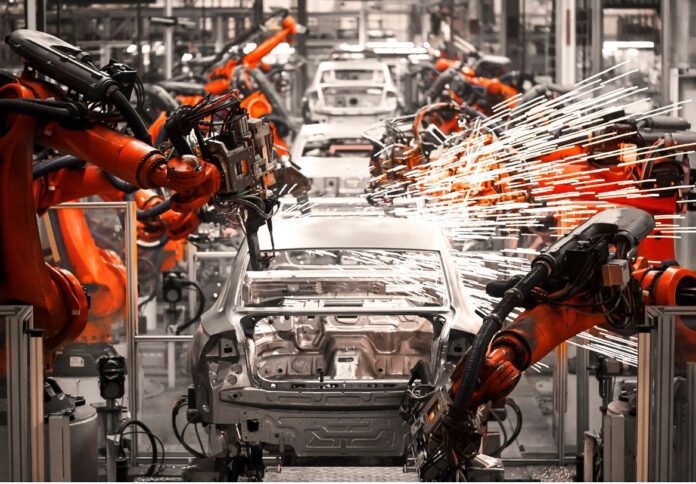

The deployment is expected to improve the production of Range Rover vehicles by enabling business-critical applications such as vision systems, IoT sensors, and automated production tools, as revealed in a media release.

The transition to a private 5G network is part of JLR’s broader push toward Industry 4.0, incorporating artificial intelligence (AI), automation, and data-driven decision-making into its manufacturing processes.

The company has moved away from traditional wired networks, citing the need for greater flexibility and real-time data transmission.

By adopting Ericsson’s high-speed, low-latency private 5G solution, JLR aims to streamline its operations and improve efficiency on the factory floor.

Manufacturing teams have reported improved workflow efficiency since the deployment of the network. Enhanced connectivity has allowed production managers to use DataOps platforms such as Litmus to analyse and act on data insights in real time.

According to JLR, private 5G has also simplified the process of provisioning new or replacement connected tools, reducing downtime and increasing agility in production line modifications.

Fujitsu has partnered with Ericsson to provide the necessary connectivity infrastructure at the Solihull plant.

The collaboration supports JLR’s potential expansion of private 5G technology to other manufacturing sites in the future.

Stephen Mason, Product Manager for Manufacturing, Global IT at JLR, said the implementation of private 5G aligns with the company’s goal of optimising efficiency through digitalisation and automation.

“As a leading global luxury automotive manufacturer, it is crucial for us to equip our teams with the tools and connectivity necessary to optimise efficiency. Ericsson Private 5G provides a robust foundation for a connected, agile, and data-driven manufacturing environment,” he said.

Ericsson’s Head of Enterprise 5G, Enterprise Wireless Solutions, Manish Tiwari, highlighted the role of private 5G in modern manufacturing.

“Private 5G is transforming manufacturing by supporting the complex connectivity needs of Industry 4.0. We are thrilled to partner with a luxury automotive leader like JLR, providing a network solution that elevates their global manufacturing capabilities,” he said.