Case Study by Entegra Signature Structures

Entegra Signature Structures is a national manufacturer of steel sheds and signature structures with globally patented designs that deliver exceptional quality and reliability.

Founded 35 years ago in Swan Hill Victoria, the Entegra team prides itself on its long history but remains firmly focused on the future, investing heavily in research and development to strengthen its position as a leading manufacturer and increase capability to deliver complex engineering tasks.

Laurie McCalman, General Manager at Entegra said the business has experienced strong growth over the past 3 years and invested heavily to expand and modernise manufacturing capability at its Swan Hill and Gympie facilities.

“The business has grown exponentially over the COVID-19 period which has resulted in a substantial increase in staffing levels nationally, predominately at our manufacturing sites.

“We are transitioning these manufacturing sites to a modern, digital workspace that paves the way for future growth and prepares our business for industry 4.0.”

Challenge

David Green, Head of Operations at Entegra is managing the transition to industry 4.0 across all facilities, and oversees the modernisation of the team’s welding capability.

“We are big on standardising processes and associated machinery to ensure the outcome from our facilities is predictable. Our manufacturing facilities had traditional transformer-based welding technology and we maintained common consumables amongst these machines for up to 20 years in some cases.”

Investing in new welding technology was important to Entegra as they understood the value of advanced manufacturing in operations.

“We always talked about ways to track welding time, which for us is the ultimate measure. It is about process control and having visibility across the business.

However, if we were going to replace one welder, we’d have to replace the lot – this was a big call for us.”

Achieving ISO9001 certification was a big achievement for Entegra, however the team recognises other relatively new standards such as AS/NZS 5131 for Structure Steelwork Fabrication would be increasingly important in the future and rely on new technologies.

“As we continue to grow, we know there will be opportunities in the short-term for larger projects that require compliance with this standard – and eventually over the next decade, we believe it will become the norm across all industry.”

Being located in regional Victoria, Entegra also identified the challenge of being able to find welders to support increased production, and explored welding automation as a way to upskill current staff and improve productivity.

“It isn’t that easy to find experienced people, especially when you’re a long way from metropolitan areas. Setting up the foundations for a welding robotic system that we could learn from made sense to support our future plans.”

Solution

With BOC already supplying its welding consumables, Entegra engaged BOC’s application specialists to start investigating new technology solutions and trialing various welders to replace existing equipment.

“It made sense to go down the path with BOC. We needed a supplier we were comfortable with. They had always been reliable with a good delivery model for getting product in.”

As the exclusive supplier of EWM digital welding machines in Australia, BOC worked with Entegra to replace all welding machines with EWM MIG inverter welders, set up to also use EWM’s industry-leading forceArc Process.

“We trialed the EWM machines a few times, and what interested us the most was the xNet software that could connect them all digitally, produce data and develop welding procedures.

“The buttons that can be installed at each work station to identify who is welding what, when and what their qualification is was also an attractive feature.”

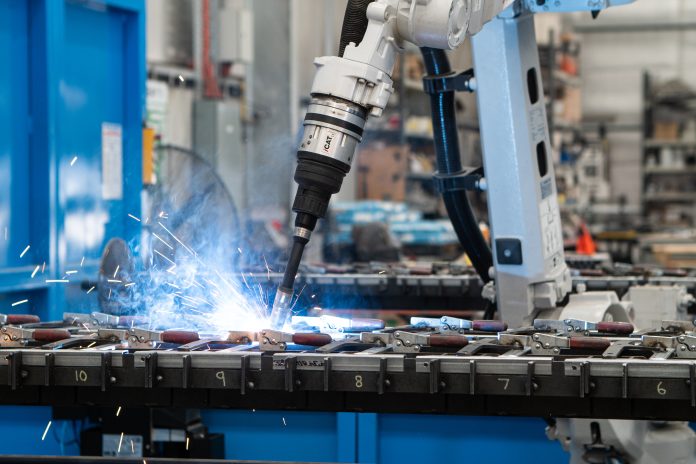

While replacing its welding machines, Entegra also commissioned its first welding automation robot with BOC and Automation & Robotic Services providing a turnkey solution. The automation system included an ABB robot paired with an EWM MIG inverter welder. This was set up to weld Entegra’s Taperflow® high volume box gutter systems.

Representatives from Entegra’s team learned the basics of robotics, and management worked with EWM experts in Germany and their local IT team to design and implement the right IT infrastructure to support the welding machines.

“There were a lot of different options. We had already invested in really good server hardware so were able to set up the welding system as a virtual machine on our server. We upgraded to fibre optics to ensure a clear line, power over ether for further expansion and gigabit switches.”

Business benefits

Building skills and future workforce

Since implementing the new welding technology, Entegra’s staff have embraced the opportunity to learn about the new technology and management has invested to upskill its workforce.

“From a management point of view, the welding machines and robot are easy to use. Many different people have been using the robot and are generally not afraid of it, which has been really good.

“We see it as an investment in our people. The robot isn’t about making it faster, but rather learning as a team. To manage robots and these new welding tools, we need to ensure we are developing our industry 4.0 experience in-house.”

Entegra is currently upskilling a senior welder to get a welding supervisors qualification to help certify welding procedures, and has also employed a mechanical engineer to spearhead further design of the welding robot and set up offline programming.

Meaningful data

The xNet software has provided meaningful data for the Entegra management team that is being reported regularly at a board level.

“With this software, we are now on the pathway to industry 4.0. To me this means being able to look at data from a machine-by-machine level, and then at an overall operational level. Then using this data to make meaningful business decisions. We haven’t even scratched the surface of what we can do.

“I am able to sit at home and see what is happening in real-time. We have been reporting weld hours at a board level and identifying trends occurring in the workshop.

Quality confidence

Maintaining the standardisation that its customers have come to expect, Entegra has continued to deliver an even higher quality product.

The EWM welding machines have delivered significant benefits, especially the forceArc process that has resulted in significant time savings.

“There wouldn’t be any welder in our team that would say there hasn’t been a huge improvement. Weld quality in terms of clean up and splatter is very noticeable.”

The better process control and qualification of the welding has also set up Entegra on a path to achieve AS/NZS 5131 safety standard certification in the future.

“This has given the sales team a lot more confidence knowing that we’re using cutting edge technology, heading towards automation and investing in our people. This all translates to a better quality and more competitive product that gives us more confidence knowing we are on a path to industry leading compliance.”

Blueprint for the future

Entegra has developed welding systems and IT infrastructure to support industry 4.0 welding manufacturing facilities, which they believe will be a blueprint for the future.

“We now have a robot that we can learn from and train. As we continue to use it and analyse data, we will have a blueprint for rolling-out automation systems at any of our sites nationally.

“If we wanted to install any IoT application down the track, we now have the IT infrastructure in place to be able to do that.

“We’re proactive, we want to be leading the industry and maintain our edge as a business is known and respected for the highest quality.”