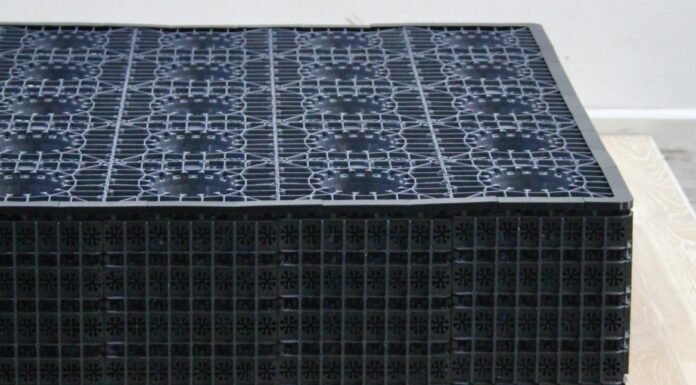

Engineers from RMIT University have developed a method to make concrete stronger and more resistant to cracking by using recycled carpet fibres, contributing to sustainability in construction.

Collaborating with Textile Recyclers Australia, Godfrey Hirst Australia, and several councils in Victoria, the research team is conducting field studies on concrete slabs made with reclaimed textiles.

Dr Chamila Gunasekara, leading the project at RMIT, explained that their technique reduces early-age shrinkage cracking in concrete by up to 30 per cent while enhancing its durability.

Cracking in reinforced concrete poses significant repair costs, estimated at AUD 8 billion annually in Australia and USD 76 billion in the United States.

By publishing their findings in Construction and Building Materials, the team demonstrated how waste carpet materials can boost concrete strength and longevity.

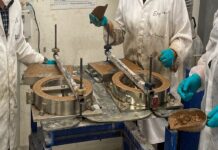

The research was conducted at RMIT’s advanced textile research facilities, where other discarded fabrics, including clothing, were also tested to strengthen concrete.

Dr Gunasekara, an ARC DECRA fellow, noted that incorporating waste carpet fibres can increase concrete’s tensile strength by 40 per cent and substantially reduce shrinkage, addressing a long-standing challenge that affects both appearance and structural integrity.

Disposing of carpets and other textiles poses a significant environmental issue. Australia ranks as the world’s second-largest consumer of textiles per capita, with an average Australian buying 27kg of new textiles annually and discarding 23kg into landfills.

Burning these waste textiles releases toxic gases, exacerbating environmental concerns. Dr Shadi Houshyar, a textile and materials scientist on the team, highlighted that 70 per cent of textile waste could potentially be converted into usable fibres, opening up opportunities in the material supply chain.

Supported by industry and government, RMIT’s team is running field trials to examine the concrete’s performance under real-world conditions.

These trials are funded by the ARC Industrial Transformation Research Hub for Transformation of Reclaimed Waste Resources to Engineered Materials and Solutions for a Circular Economy (TREMS), led by Professor Sujeeva Setunge, and are backed by early-career research grants.

The team is also collaborating with Professor Andrzej Cwirzen from Sweden’s Luleå University of Technology on computational modelling.

Several peer-reviewed publications document the findings, with titles including Enhancement of Concrete Performance and Sustainability Through Incorporation of Diverse Waste Carpet Fibres in Construction and Building Materials and related research in journals such as Journal of Building Engineering, Journal of Materials in Civil Engineering, and ACI Materials Journal.