Media Release

Australia’s national science agency, CSIRO, is paving the way for a new era of manufacturing with silicone, with the development of their next generation silicone resins for making 3D printed medical parts.

A relative newcomer to the global 3D print market, silicone has enormous potential for 3D printing and is estimated to be worth over USD$91 billion dollars by 2026.

But as a new technology, 3D printing with silicone has its challenges – low resolution and slow speed being the key issues.

According to CSIRO polymer chemist, Dr Ke Du, current silicone resins are also restricted for use on specialised printers, which can be expensive.

To solve these problems, Dr Du and her colleagues have developed a family of new silicone products.

“Our unique biocompatible resins boast a suite of excellent attributes,” Dr Du said.

“What’s more, they can be used with off-the-shelf printers, without the need for modification”.

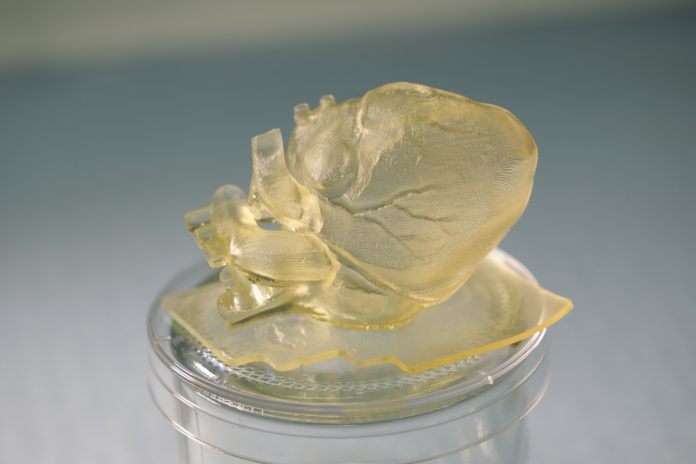

The resins are non-cytotoxic and are capable of printing complex designs in high resolution, including irregular shapes, thin walls and hollow structures.

The printed silicone parts produced with the resins have tunable mechanical properties, making them customisable for different applications.

Team leader of CSIRO’s Biomedical Polymer Chemistry group, Dr Tim Hughes, said the resins have applications in 3D printed medical devices and customised products such as dental devices, hearing aids and cochlear implants, prosthetics, and other patient specific medical devices.

“We believe the resins may even help fast track prototyping some of these biomedical devices,” Dr Hughes said.

Parts made with the resins are super soft and have great compressive elasticity and high transparency.

The silicone resins work on the digital light processing 3D printer – light wavelength range from 360-500 nm – and they are also accessible to common commercially available desktop DLP printers.

The technology is likely to also work in stereolithography (SLA) 3D printers and perhaps with modification in other photocurable 3D printers such as inkjet and extrusion.

A surprising novel feature is the resin’s superglue properties. The research team discovered the resins can easily affix glass and metal, opening up an entirely new market as a construction adhesive.

The team has patented their novel silicone resins and they are seeking industrial partners to help commercialise the product.