Australia’s national science agency CSIRO has collaborated with corporate advisor RFC Ambrian to establish a new company to commercialise electrolysis technology that the agency said can produce hydrogen with 30 per cent less electricity in a push to decarbonise heavy industry.

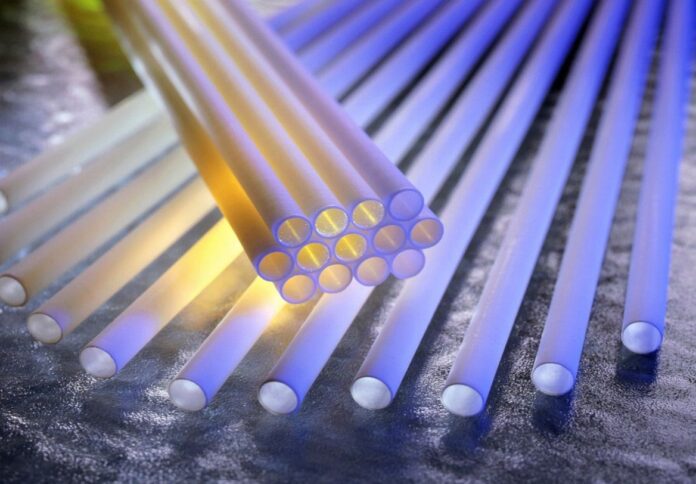

The newly formed Hadean Energy aims to promote the development of the CSIRO’s tubular solid oxide electrolysis (SOE) technology, which it claims would dramatically cut hydrogen production costs and industry emissions through process efficiencies, the agency said in a news release.

CSIRO said it will now establish a pilot scale demonstration plant at BlueScope’s Port Kembla Steelworks on the New South Wales south coast to trial the technology in an industrial setting.

According to the International Energy Agency, demand for hydrogen is predicted to rise 138 per cent by 2030, however, high production costs and energy inputs are major barriers to developing green hydrogen.

Dr Sarb Giddey, CSIRO’s principal scientist on hydrogen research, said the development of tubular SOE technology is a vital effort aiming at creating more economical and efficient hydrogen to assist industry in substantially decreasing emissions.

“CSIRO’s SOE technology has the potential to produce hydrogen at a higher efficiency and lower cost for integration with industrial processes,” Dr Giddey said.

“It allows industrial waste heat to be integrated back into the industrial processes, which decreases the electrical energy required to produce hydrogen or syn-gas by up to 30 per cent,” he added.

The agency further revealed that the hydrogen product can be utilised as a feedstock for the production of chemicals such as ammonia, petrochemicals, methanol, dimethyl ether, and sustainable fuels, as well as in low-emission steelmaking and heavy transport.

The absence of platinum group metals and nickel minimises reliance on global supply systems, CSIRO said.

Beginning in April 2024, an experiment with BlueScope will be conducted. The technology will be shown at a larger scale, and the trial’s other findings and integration features will prove the equipment’s technical resilience.

Tania Archibald, chief executive of Australian Steel Products, stated that BlueScope supports the pilot project because it coincides with their environmental goals.

“SOE has the potential to dramatically reduce the cost of hydrogen for low emissions steelmaking. The improved efficiency of SOE systems reduces energy consumption and reduces the electrical infrastructure required by electrolysers.” Archibald explained.

Meanwhile, according to Stefan Skorut, CIO of RFC Ambrian, the technology is ideally positioned to meet the existing industrial hydrogen industry, which is now nearly entirely sourced from fossil fuels.

“While SOE is the most efficient method of electrolysis, green hydrogen and synthetic fuels will remain uneconomic unless we address the scalability and cost of electrolysers,” Skorut said.

To learn more about the startup, you may visit this hadeanenergy.com.au.