Australia’s growing focus on sustainability has placed bioplastics under the spotlight, with a new report by the CSIRO revealing their potential and pitfalls.

The State of Bioplastics in Australia report underscores a significant hurdle: unclear labelling and disposal practices, which often lead bioplastics to end up in landfills or contaminate recycling and composting systems.

The findings come amid a global plastic production boom, currently at 460 million tonnes annually, with projections to double by 2040.

Traditional fossil fuel-based plastics account for 3 per cent of global greenhouse gas emissions, amplifying the need for sustainable alternatives like bioplastics.

Dr Albert Ardevol, CSIRO’s Plastic Packaging Research Lead, said bioplastics offer promise in reducing plastic pollution and dependence on fossil fuels. However, he cautioned that consumer confusion over disposal is hindering their effectiveness.

“Bioplastics cover a wide range of polymer types and uses, but there is confusion around terminology and how to process bioplastics after use,” Dr. Ardevol explained.

“Australia doesn’t have standardised labelling so it’s hard for consumers to understand the different types of materials and how they integrate into existing waste management systems.”

While bioplastics are often touted as more sustainable alternatives, improper disposal can have adverse environmental impacts, including methane emissions from landfills, the report noted.

Globally, bio-based plastic production has surged, more than doubling since 2010 to reach 2.18 million tonnes in 2023. Packaging remains the dominant application.

Yet, in Australia, bioplastics account for only 1% of total plastic use, presenting both a challenge and an opportunity for growth.

“Bioplastics make up only 1 per cent of plastic used in Australia which provides a significant opportunity to create commercial opportunities while reducing impacts on the environment,” said Dr Ardevol.

Polylactic acid (PLA) is the most commonly used bioplastic in Australia, primarily in packaging, but most of it ends up in landfill. In contrast, polyhydroxy acids (PHA) are more versatile and can decompose in various environments, making them viable for single-use items.

Dr Deborah Lau, CSIRO’s Ending Plastic Waste Lead, stressed the need for design standards and specialised infrastructure to support the bioplastics industry.

“Bioplastics need to be designed and considered within the broader plastic waste system,” Dr Lau said.

“Capacity and infrastructure for processing bioplastics needs to be developed, as they are not accepted in most existing waste collection streams.”

Australia’s bioplastics industry relies heavily on imported raw materials, primarily from Thailand and Brazil.

Locally, raw materials like sugarcane, corn sugar, and starches are used to produce bioplastics such as PLA, BioPE, and PHA. However, these often require specialised waste management facilities, which are scarce.

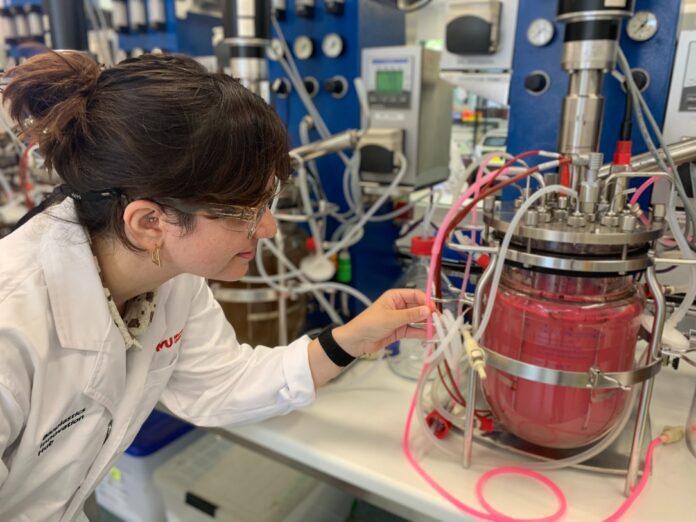

The CSIRO has taken proactive steps to address these challenges. Its Bioplastics Innovation Hub, established in collaboration with Murdoch University, is working on developing 100 per cent compostable plastics suitable for both industrial and home composting.

The State of Bioplastics in Australia report is part of CSIRO’s broader Ending Plastic Waste research initiative, aiming to transform how plastics are made, used, and disposed of.

With growing environmental concerns and consumer demand for sustainable alternatives, the report highlights the pressing need for investment in infrastructure, innovation, and clear labelling standards to unlock the full potential of bioplastics in Australia.