Over the past decade, more than 1,850 workers have lost their lives to traumatic injuries in Australian workplaces. Even more alarming, over 1.1 million workers have filed serious compensation claims for injuries resulting in more than a week of lost work time. That is approximately one in every 12 workers facing significant workplace injuries.

These numbers paint a grim picture of workplace safety across Australian industries, with steel manufacturing being particularly high-risk. However, a technological revolution is on the horizon, promising to dramatically reshape the safety landscape of Australia’s steel manufacturing sector.

As Australia’s steel industry grapples with the dual pressures of global competition and stringent safety standards, many experts have pointed to artificial intelligence and robotics as the compelling solution. It is not just about boosting productivity but fundamentally transforming how Australia approaches safety in one of its most vital yet hazardous sectors.

This is the argument Professor Cori Stewart, founder and CEO of Advanced Robotics for Manufacturing (ARM) Hub, presented at the recent Finding Your Productivity Edge with Robots and AI.

The role of AI in boosting safety

While automation is crucial, AI’s role in enhancing safety at steel mills extends far beyond replacing human workers in dangerous tasks. AI systems are being deployed to predict potential hazards, optimize processes, and create a more proactive approach to safety management.

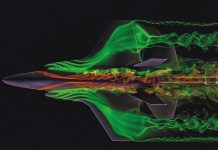

Pointing to Australian successes in AI and robotics, Professor Stewart cited Boeing Australia’s delivery of the Ghost Bat autonomous warfighting aircraft and the automation of more than 700 Caterpillar, Komatsu and Hitachi haulage trucks in the Pilbara mines.

These achievements demonstrate Australia’s capacity to develop and implement advanced AI and robotics solutions in complex, high-risk environments.

Looking to the future, Professor Stewart advocates for a holistic approach to implementing AI and robotics in the steel industry.

“Often we hear about companies creating downstream value (how they create jobs or attract vocational education training (VET) educated staff or low skilled workers), and we also need to ask different questions about how to create upstream value using highly skilled jobs, jobs that may not even exist yet but will soon; indeed it means companies investing more in high-value skills and high-value products than they are likely to now.”

This vision calls for steel manufacturers to invest not just in the technologies themselves, but in the high-value skills and products that will drive the industry forward. It suggests a future where safety, productivity, and innovation are all linked and powered by AI and robotics.

Shaping tomorrow’s Australian steel production

Undoubtedly, AI and robotics are set to become cornerstone technologies in tomorrow’s workplace safety. Many industry leaders hope that this means safer work environments and more innovative workplaces. The challenge now lies in embracing this change. This means investing in the necessary skills and infrastructure while ensuring that the safety and well-being of workers remain at the forefront.