Boral has secured $24.5 million in Australian Government funding to support carbon-reducing adaptations at its Berrima Cement Works, a move that could reduce CO2 emissions from cement manufacturing by up to 100,000 tonnes annually.

The funding, announced by Minister for Climate Change and Energy Chris Bowen MP at the Berrima site, comes from the government’s Powering the Regions Fund.

The grant is intended to help decarbonise existing industries and contribute to Australia’s broader emission reduction targets, the company said in a news release.

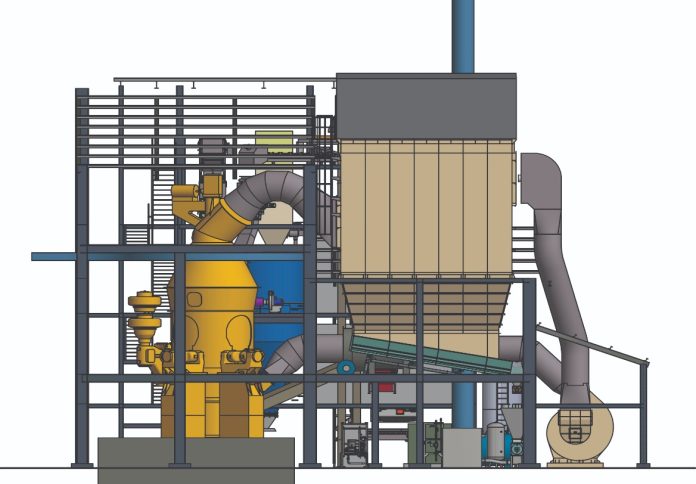

Boral said it will use the funds to supplement its investment in a specialised grinding circuit and supporting infrastructure at Berrima Cement Works.

The initiative is expected to increase the proportion of alternative raw materials (ARMs) used in the kiln feed, reducing reliance on limestone, which releases CO2 during clinker production.

Boral CEO Vik Bansal welcomed the Federal Government’s support, stating, “We believe that [the] grant signifies a vote of confidence from the Federal Government on Boral’s decarbonisation and innovation efforts, amidst our immense progress in an industry that is highly carbon intensive and operates in a hard-to-abate sector.”

Boral’s Berrima Cement Works, which supplies up to 40 per cent of cement in New South Wales and the Australian Capital Territory, is a key manufacturing site for the company.

According to Boral, the new project will enable it to increase the proportion of alternative raw materials in the kiln feed to 23 per cent, up from the current 9 per cent.

This shift is expected to lower the amount of limestone used, which in turn will cut process emissions.

“Boral, along with the entire cement and concrete industry in Australia, has been seeking pathways to lower its CO2 emissions and contribute to Australia’s ambition to reach Net-Zero by 2050,” said Dr Ali Nezhad, Head of Innovation and Sustainability at Boral.

“By increasing the proportion of ARMs in the kiln feed, less limestone and shale is added to the kiln, lowering process emissions and the carbon intensity of the resulting clinker.”

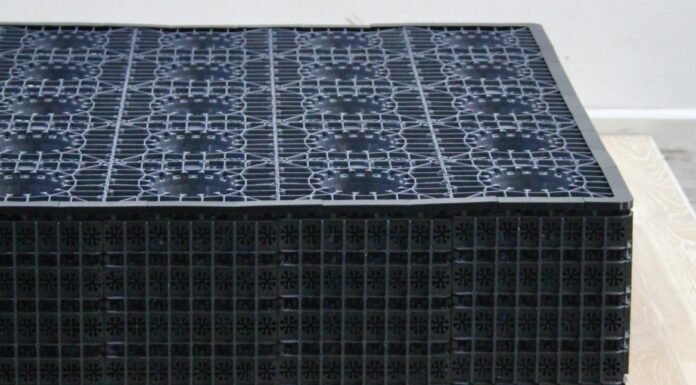

The company said it plans to source ARMs from by-products of steel manufacturing and industrial waste, including granulated blast furnace slag, steel slag, cement fibre board, fly ash, and fine aggregates from recycled concrete.

These materials require lower heating temperatures compared with limestone, resulting in reduced energy consumption.

According to Bansal, the initiative builds on Boral’s previous investments in alternative fuel usage.

“As a result, Boral is on track to remain below the baseline safeguard mechanism requirements. We are also very pleased to be investing in a crucial and historic part of Australia’s manufacturing and construction sector,” he said.

The project is expected to be fully operational by 2028, following detailed process designs, procurement, construction, installation, and commissioning phases.

It will complement Boral’s ongoing alternative fuels initiative, which aims to reduce fuel-based emissions at the site.

Last year, the company upgraded its carbon-reduction technology at Berrima, with a Chlorine Bypass system designed to facilitate greater alternative fuel usage.

“This project plays a key role in Boral’s broader decarbonisation pathway by reducing process emissions, which are the largest and most difficult to abate emissions source in cement manufacturing,” Nezhad explained.