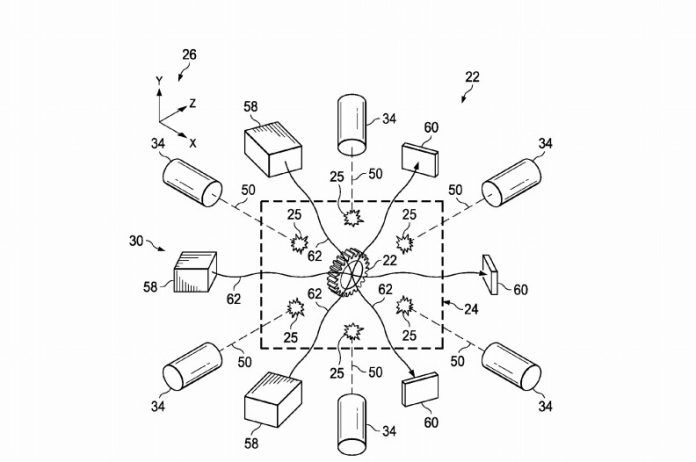

Aircraft manufacturer Boeing has patented a new technique that will 3D print levitating objects by using multiple 3D printers at once.

According to the company, the 3D printers will extrude material with diamagnetic properties and the technology will create magnetic fields that will hold the initial 3D printed material in place.

This initial 3D printed material, called “the nugget”, will then be built upon by the multiple 3D printers. In other words, the nugget will collect the material, layer by layer and actually grow into an airplane part.

Boeing says that levitation is the key word here since a levitating object can be easily manipulated and rotated so that material can be added on all sides; the rotation part will be handled by the magnetic fields.

Another great aspect of 3D printing levitating objects? – Speed. Using many 3D printers simultaneously would significantly speed up the process.

Boeing’s revolutionary technology is called “Free-Form Spatial 3D printing Using Part Levitation”.

“There is a need for an AM method and apparatus that eliminates the need for a platform and/or support materials to stabilise the part during the fabrication process, and which removes limitations on the types of features that can be formed, allowing full body 3D printing of complex parts,” Boeing states.

It sounds like something out of this world, but thanks to PatentYogi, there’s a video available online that paints a pretty clear picture of Boeing’s vision.

Check it out.