Media Release by Biax Foundations

When Vogue Homes, an award-winning residential building company based in south-west Sydney, was looking for a point of difference in its builds, it turned to revolutionary building product Biax, an eco-friendly and user-friendly foundation system for concrete slabs.

Vogue Homes has been in operation for over 15 years, mainly working on residential homes, from house and land packages right through to custom builds. The business averages around 40-50 homes per year, but 2022 saw a big leap, with 100 builds on the schedule, thanks to Covid incentives and a different sales approach.

Rod Harvey, Vogue Homes Construction Manager, says that using the Biax product has helped Vogue Homes stay ahead of the game.

“The building industry is seeing a strong shift to more sustainable practices and products, and soon enough it will become mandated that we have to use certain products that benefit the environment, so we knew we needed to make a change and set ourselves up for the future, especially with our use of waffle pod foundations,” Rod says.

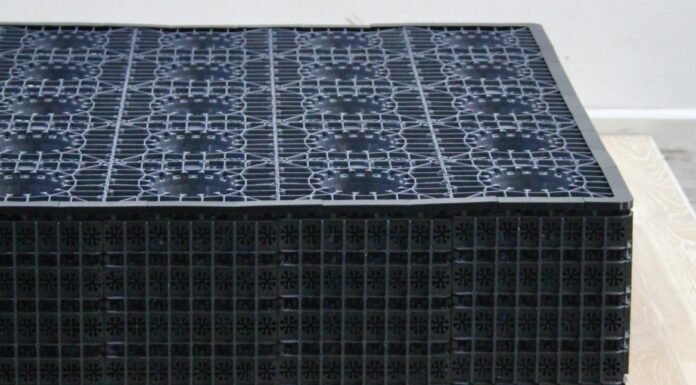

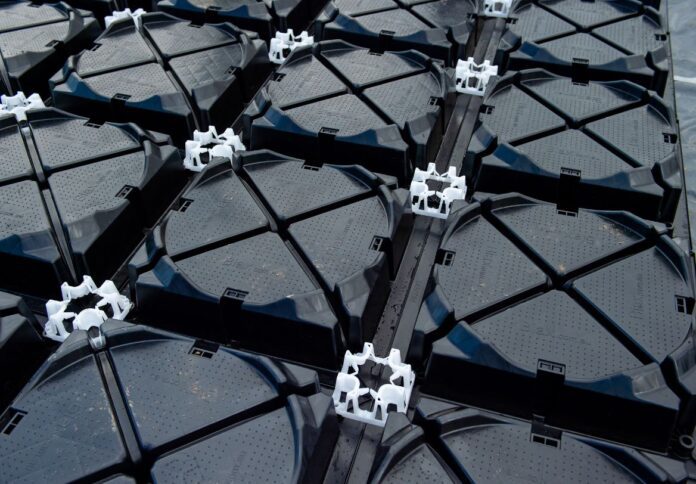

Biax represents a clever rethinking of the waffle pod, replacing unsightly, hard-to-manage, environmentally damaging polystyrene blocks with a compact, lightweight and sustainably produced product. Biax retains the best elements of the waffle pod design, and goes further with the design properties to not only save on concrete and steel, but replaces the bulky styrene blocks with compact, recycled plastic pods.

Rod says that there are benefits beyond sustainability credentials when it comes to using Biax on building sites.

“Biax is quicker to install, we’re probably saving an hour or two using Biax over waffle pods, as well as a lot of cost savings per build. The height of Biax pods compared to waffle pods means we’re saving costs on concrete as well as site excavation costs, and there is also cost savings with the steel as the engineering allows for reduced specifications. The rib spacing is closer in the Biax product, meaning there are gains in slab strength. We’ve reviewed all our slabs poured to date using Biax, and there has been minimal to no evidence of any cracking, including hairline shrinkage cracks – meaning it’s durable over time.

“Biax is designed to take up less room on site too because it’s stackable, we’re actually reducing our waste and environmental impact. Often you find with waffle pods they are bulky, and when the wind picks up they can end up all over the site, but Biax doesn’t have that problem,” Rod says.

“When we started using Biax a few years ago it was on just a few sites, now we’re sitting at over 95% of our builds using Biax. 2023 is looking even bigger for us with about 100 jobs in the pre-construction phase already and over 200 sales in the pipeline, and the aim is to have nearly 100% of those using Biax. It really is a game changer for us.”