In a significant development for South Australia’s copper industry, the South Australian Government has initiated the application and assessment process for BHP’s proposed smelter and refinery expansion at Olympic Dam.

The expansion aligns with BHP’s recently outlined phased approach to increase copper production in South Australia, BHP said in a news release.

According to the company’s FY24 full-year results released earlier this week, BHP aims to ramp up its copper output to 500,000 tonnes of refined copper cathode by the early 2030s, with the potential to further expand to 650,000 tonnes by the mid-2030s.

This would represent an increase from the approximately 322,000 tonnes produced in the last financial year.

Anna Wiley, BHP Asset President Copper South Australia, highlighted the importance of this development.

She stated, “Today’s announcement is an important step for BHP and the South Australian Government as we work together towards our shared ambition to significantly increase copper production in this state.”

Wiley further emphasised BHP’s ongoing efforts, noting, “We are already growing BHP’s copper production in South Australia with projects and studies underway at all of our operating sites, and we’re moving at pace to potentially double our current production by the middle of the next decade.”

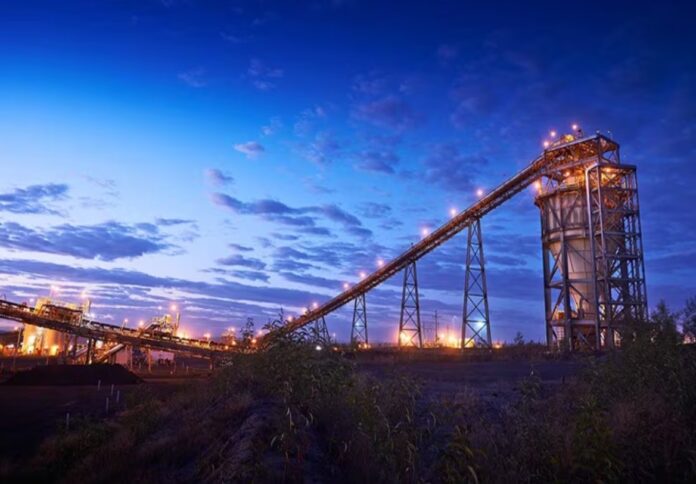

BHP’s copper operations in South Australia are centred around the Olympic Dam, Prominent Hill, and Carrapateena underground mines, which supply copper concentrate to the Olympic Dam smelter and refinery complex.

This facility is key to producing refined copper cathodes. Additionally, BHP is advancing its Oak Dam exploration prospect, which recently reported an Inferred Mineral Resource of 1.34 billion tonnes at 0.66 per cent copper grade and 0.33 grams per tonne gold grade.

Within this, a higher-grade mineralisation area contains 220 million tonnes at 1.96 per cent copper grade and 0.68 grams per tonne gold grade, based on a 1 per cent copper cut-off.