Media Release by BASF

BASF introduces the novel X3D technology, a new additive manufacturing technology for catalysts based on 3D printing.

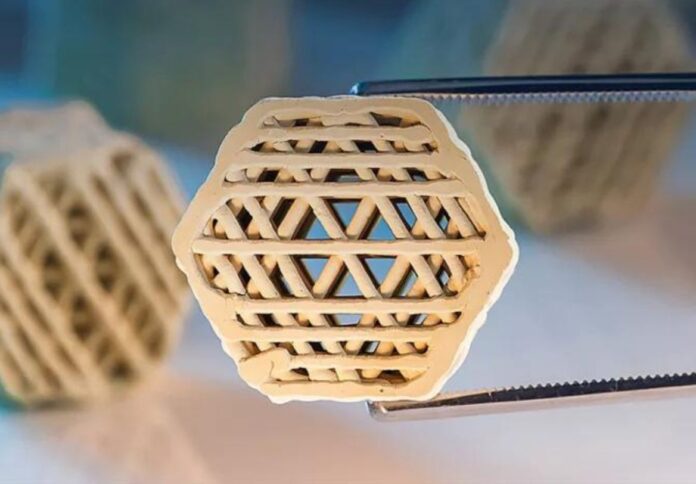

Catalysts produced with this technology feature an open structure, resulting in a reduction of the pressure drop across the reactor and a high surface area, significantly improving the catalysts’ performance. BASF has capabilities to supply commercial quantities.

The technology offers a greater freedom of catalyst design compared to conventional production technologies. It brings catalysts’ performance to the next level and helps to customize catalysts to customers’ specific conditions and needs by designing infill pattern, fiber diameter and orientation.

Customers can benefit from an increased reactor output, higher product quality and lower energy consumption. The novel catalysts are mechanically robust and proven in commercial plant operation externally and for several years in BASF.

BASF can apply the technology to a wide variety of existing catalytic materials, including base or precious metal catalysts as well as carrier materials. BASF’s Sulfuric Acid catalysts O4-111 X3D and O4-115 X3D are the first catalysts produced with the new technology and are used in industrial plants.

“With this technology, we are able to provide catalysts that are tailored to our customers’ needs to help significantly boost their plant performance while reducing energy consumption and increasing sustainability at the customer level”, said Detlef Ruff, Senior Vice President, Process Catalysts at BASF.

“BASF’s technical service team will work with customers to identify the best catalytic technology for their individual projects,” said Chris Wai, Vice President, Global Chemical Market Catalysts at BASF.