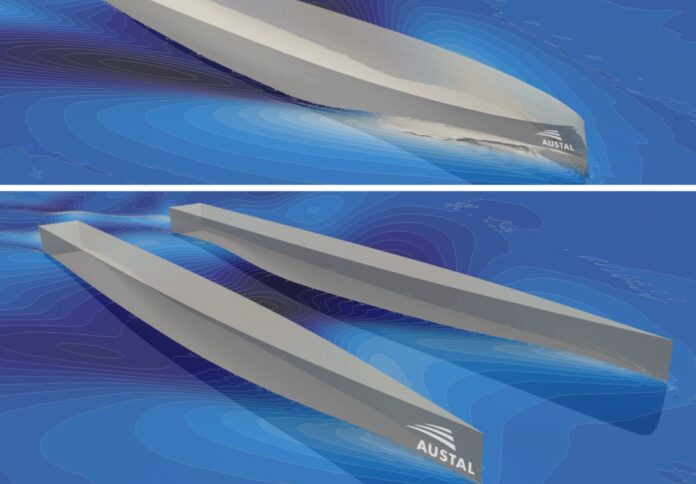

Austal Australia has introduced its new artificial intelligence toolset, DeepMorpher, to help its Australian designers explore broader design spaces while significantly reducing resource requirements for complex ship hull optimisation routines.

The DeepMorpher toolset was developed amid the rapid evolution of market environments that expose the need for an innovative approach towards providing optimum solutions for emerging trends, such as autonomy, decarbonisation, and new naval capabilities.

Austal Australia created the toolset to achieve greater efficiencies and productivity in design and engineering.

Max Haase, a development hydrodynamics specialist at Austal Australia and co-author of a newly published research article “DeepMorpher: Deep learning-based design space dimensionality reduction for shape optimisation,” said the toolset reduces the company’s reliance on domain expertise and enables greater focus on maximising outcomes based on customer requirements.

“Artificial intelligence and machine learning has broadened and accelerated our optimisation process, delivering greater options, more quickly for our customers,” Haase said.

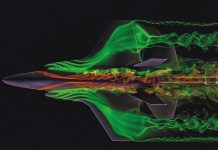

“With the support of high-performance computing (HPC) provider DUG Technology, we can reduce the timeframe for hull form optimisation in conjunction with computational fluid dynamics (CFD) by an order of magnitude,” he added.

DeepMorpher can also be used for arbitrary shape optimisation, including many other maritime, aerospace, or engineering applications, Austal said in a media release.