Australian scientists have discovered a new magnesium-lithium alloy that has proven to be corrosion resistant and is set to revolutionise the manufacturing industry.

This new lightweight material has an ultra-low density and could significantly reduce the weight of cars and planes, improve fuel efficiency and greatly reduce global greenhouse gas emissions.

The researchers, led by a team at the University of New South Wales, used the Australian Synchrotron to turn this discovery into the first crucial step towards the mass production of “stainless magnesium”.

The Australian Synchrotron is the nation’s world-class research facility that uses accelerator technology to produce a powerful source of light – x-rays and infrared radiation – a million times brighter than the sun.

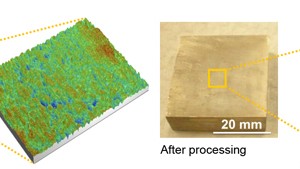

The new alloy is capable of forming a protective layer of carbonate-rich film upon atmospheric exposure, “making it immune to corrosion” much like the way a layer of chromium oxide enables the protection of stainless steel.

“Many similar alloys have been created as researchers seek to combine the incredible lightness of lithium with the strength and durability of magnesium to develop a new metal that will boost the fuel efficiency and distance capacity of aeroplanes, cars and spacecraft,” said Professor Michael Ferry, from UNSW’s School of Materials Science and Engineering.

“This is the first magnesium-lithium alloy to stop corrosion from irreversibly eating into the alloy, as the balance of elements interacts with ambient air to form a surface layer which, even if scraped off repeatedly, rapidly reforms to create reliable and durable protection.”

The researchers claim that viewing unprecedented structural detail of the alloy through the Australian Synchrotron will enable them to work toward commercialising the new metal.

The team also includes researchers from Monash University, CHALCO, and Nanjing University of Technology in China.

“Through our close collaborator, Dr Yang Xiao, we have strong ties to the Zhengzhou Light Metals Research Institute of CHALCO in China. We’re aiming to take the knowledge gleaned at the Australian Synchrotron to incorporate new techniques into the mass-production of this unique alloy in sheets of varying thickness, in a standard processing plant,” said Professor Nick Birbilis from the School of Materials Science and Engineering at Monash University.

“These panels will make many vehicles and consumer products much lighter and, eventually, just as durable as today’s corrosion-resistant stainless steel, another example of how advanced manufacturing is unlocking the potential of materials that have been under investigation, in too narrow a manner, for centuries.”

Their findings have been published in the current edition of Nature Materials.