Aurora Labs, a leader in industrial 3D printing in Australia, announced the signing of a Memorandum of Understanding (MoU) with Australian defence UAS developer Innovaero Pty Ltd.

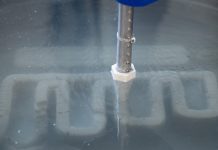

This strategic collaboration aims to combine Innovaero’s expertise in aerospace systems development with Aurora Labs’ advanced 3D printing capabilities to innovate and enhance the manufacturing of metal UAS components.

Additionally, Aurora Labs will supply Innovaero with micro gas turbines for testing on their current UAS platforms, the company said in an ASX announcement.

Innovaero, now a joint venture between Aerovation Technologies Pty Ltd and BAE Systems Australia Pty Ltd, the wholly owned subsidiary of UK-listed BAE Systems Plc, is based in Western Australia.

The company has extensive capabilities in designing, manufacturing, and certifying products for the aviation industry.

Known for its cutting-edge OWL loitering munitions and as the developers of both the Nearmap Ltd and Spookfish Ltd camera systems, Innovaero will collaborate with Aurora Labs to apply advanced 3D printing technologies to the emerging field of UAS manufacturing in Australia.

The MoU outlines the exchange of information regarding printing and aerospace technologies to assess and improve the performance, reliability, and productivity of 3D printed parts for UAS.

This partnership also includes collaboration on Aurora Labs’ Micro Gas Turbine propulsion system. The agreement has a term of two years and will automatically extend unless terminated by either party.

Mike von Bertouch, co-managing director of Innovaero, commented: “This is an exciting opportunity for Innovaero to collaborate with A3D to explore a range of possible solutions for micro-turbine propulsion in real-world applications.”

He added, “Additionally, other allied opportunities in the aerospace domain may present pathways for future exploitation with the unique additive manufacturing processes developed by A3D. Innovaero welcomes the opportunity to work with A3D in road-testing those opportunities.”

Rebekah Letheby, CEO of Aurora Labs, added: “A3D is delighted to engage in this MoU with Innovaero. The application of Aurora Labs’ 3D metal printing technology to various UAS platforms presents a significant opportunity to accelerate the development and market introduction of quality UAS components and micro gas turbine propulsion systems.”

She continued, “By integrating our components at this early stage in our development, we can better understand and optimise the performance of printed parts, likely paving the way for advancements in technology and performance of these UASs and propulsion systems.”