Australian Strategic Materials (ASM) has announced that its Korean research and development partner, ZironTech has successfully produced a titanium metal alloy with the patented reduction process at the joint venture’s commercial pilot plant in South Korea.

According to the ASX release from ASM, energy costs in metal production typically account for 30-40% of total costs. The production of the titanium metal alloy utilising 45% less power indicates significant cost benefits to ASM’s integrated business strategy. This will be further optimised as the metallisation program progresses.

ASM’s Managing Director, David Woodall said: “This is a significant milestone in the development of our integrated business plan that includes clean metal production from the development of the Dubbo Project in Central West NSW. The clean metal technology can be applied to all the products from the Dubbo Project.”

Located in central-western NSW, the Dubbo Project was developed to supply globally significant quantities of zirconium and rare earth materials, as well as contribute to the niobium and emerging hafnium industries. These materials are in high demand for a range of existing and future technologies – in particular clean energy and transportation, where they are used in high volumes.

“This production of titanium metal alloy from titanium oxide feed is a first step in the ASM strategy of value adding to the output from its polymetallic Dubbo Project, with its large in-ground resource of zirconium, rare earth elements (including yttrium), niobium, and hafnium. ASM’s investment in downstream processing will improve the economics of its Dubbo project, as well as ASM leading the worldwide commercialisation of this breakthrough metallising technology,” said Mr. Woodall.

ZironTech is now progressing the second phase of its metallisation strategy focusing on the production of zirconium metal in July 2020.

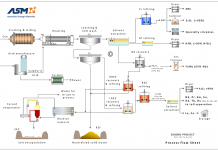

Image from ASM website