ASX-listed manufacturer Calix Limited has received a $947,035 grant from the Australian Renewable Energy Agency (ARENA) to evaluate the feasibility of a low-emissions method for reducing iron.

The funding will support an 11-month study aimed at developing a Zero Emissions Steel Technology (ZESTY) iron demonstration plant.

A $1.96 million pre-Front End Engineering and Design (FEED) and FEED study seek to scope the design for a proposed demonstration scale Hydrogen Direct Reduced Iron (HDRI) production plant using Calix’s proprietary ZESTY plant.

Most steel manufacturers in the world use a carbon-intensive blast furnace technology that utilises coking coal at numerous stages of the production process.

HDRI is intended to serve as a suitable feedstock for electric arc furnaces that creates steel using only electricity.

Powered by renewables, electric arc furnaces can reduce the emissions from the processes stage to virtually zero.

Today’s electric arc furnace steel facilities generally use Direct Reduced Iron produced with natural gas.

Meanwhile, HDRI is designed to use renewable hydrogen to eliminate the need for natural gas and cut emissions from iron reduction.

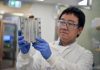

The new process builds on the existing Calix Flash Calciner technology, which is used for a variety of industrial processes.

“This project aims to further develop a homegrown Australian technology that we believe, together with Australia’s leading iron ore and renewable energy resources, can help make Australia a leading exporter of not just iron ore, but green iron and green steel,” said Calix Managing Director and CEO Phil Hodgson.

Reducing emissions from steel manufacturing is part of ARENA’s strategic priority as it focuses on decarbonising the steel and aluminium value chains.

“Decarbonising heavy industries like steel is a big challenge, and a big opportunity, and ARENA is looking to support companies like Calix that are developing potential solutions,” said ARENA CEO Darren Miller.

“For Australia and the world to meet our net zero targets, we’ll need to develop new ways of making materials the world relies on,” Miller said.