At the latest Apple launch event held Tuesday, the tech giant introduced its highly anticipated iPhone 15 Pro series, packed with industry-first innovations, including the use of Grade 5 titanium enclosure in its manufacturing process.

Apple said this Grade 5 titanium, also known as Ti-6Al-4V, is capable of exceptional tensile strength and corrosion resistance.

Typically utilised in industries like aerospace, racing, and prosthetics manufacturing, Grade 5 titanium is reserved for applications where the balance of strength, formability, and weight is critical.

During the event, Apple touted the use of titanium in the iPhone 15 Pro’s design, describing it as “the most premium material” ever incorporated into an iPhone enclosure.

Notably, it is the same alloy used in the construction of the Mars Rover, highlighting its reliability in extreme environments.

Apple mentioned that one of the standout benefits of titanium is its remarkable strength-to-weight ratio, which allows the company to create a robust and durable iPhone while maintaining a surprisingly lightweight design compared to traditional stainless steel enclosures.

The titanium encases a new aluminium sub-structure, which is bonded using a solid-state diffusion process.

Apple said it employed an innovative thermo-mechanical method to join these two metals with high strength, ensuring both durability and structural integrity.

The use of aluminium on the interior of the iPhone 15 Pro provides synergistic properties with the titanium enclosure, aiding in thermal dissipation and further reducing the device’s overall weight.

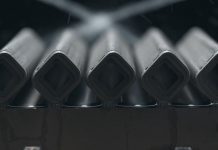

Apple’s meticulous attention to detail is evident in the titanium enclosure’s refined brush texture, achieved through a multi-step process involving precision machining, brushing, and blasting.

To enhance both aesthetics and durability, Apple opted for a Physical Vapor Deposition (PVD) coating, which adds a layer of protection and introduces a range of stunning colours.

These Apple-designed coatings are engineered with nanometre precision and require up to 14 hours to complete, resulting in four distinct finishes.

Users can choose from Black Titanium and White Titanium, which harmonise with the back glass, Blue Titanium, highlighting the material’s elegance, and Natural Titanium, celebrating its raw metallic nature.

In addition to its material selection, the iPhone 15 Pro introduces a new internal chassis architecture aimed at making the device more repairable.

The tech giant said a new structural frame allows for the easy replacement of the back glass, contributing to Apple’s sustainability goals.

Remarkably, the entire aluminium sub-structure is made from 100 per cent recycled aluminium, a first for the iPhone, aligning with Apple’s commitment to increasing the use of recycled materials and its 2030 environmental objectives.

By utilising materials like Grade 5 Titanium and recycled aluminium, Apple said it not only aims to provide users with exceptional products but also contributes to environmental conservation by reducing the consumption of finite natural resources.

The company said the iPhone 15 Pro represents a leap forward in smartphone design and sustainability, setting new standards for the industry.