The additive manufacturing service provider produced an aluminium personnel recovery davit (crane), intended for naval applications with its proprietary ‘WAM®’ additive manufacturing technology, on behalf of Austal.

According to the statement from AML3D ‘as part of the qualification process, a three metre long personnel recovery davit was designed and produced to meet international and naval specifications. The assembly was then function tested to more than twice its design working load. Following the successful load test, non-destructive and destructive testing, the results were reviewed by all parties before the final verification statement was issued’.

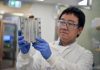

“We’re proud to have been able to partner with Austal and demonstrate the advantages of our proprietary Wire Additive Manufacturing (WAM®) capabilities in the creation of the Davit Arm. Additionally, we are equally as excited to see this WAM® printed component receive an official verification statement by DNV. This now offers averification pathway for a much wider range of components that can now follow a similar validation process” said Andy Sales, AML3D Chief Executive Officer.

According to AML3D, the component was subjected to extensive testing by the John de Laeter Centre and the Curtin Corrosion Centre at Curtin University.

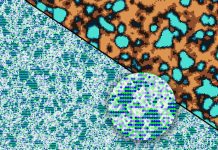

‘Researchers utilised advanced microanalysis instrumentation to generate high quality microstructural information and images. In addition, the mechanical and corrosion characteristics were assessed and compared against established marine grade metals,’ statement.

Austal Chief Digital Officer, Andrew Malcolm said the successful team up with AML3D and Curtin University on the additive manufacturing project highlighted the many opportunities to pursue emerging technologies with Australian industry.

“Austal Australia has been working with AML3D since 2019 on the development of hybrid manufacturing approaches that put robotics side by side with our highly skilled tradesmen and women to fabricate large complex structures,” Mr Malcolm said.