Aluminium giant Alcoa will proceed with a trial of a steam recycling technology aimed at reducing emissions at its West Australian Wagerup facility after an Australian Renewable Energy Agency-backed study found the technology to be not only feasible but also less expensive.

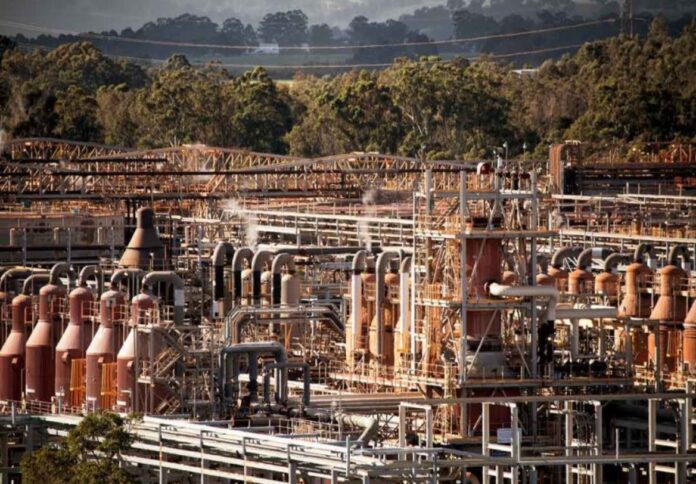

According to an article by ARENA, Alcoa intends to install a 4 MW Mechanical Vapour Recompression (MVR) module powered by renewable energy at its Wagerup alumina refinery in Western Australia, south of Perth.

The technology, which is part of Alcoa’s Refinery of the Future project, is said to address the most emissions-intensive stage of alumina refining by recycling waste steam that would otherwise be released into the atmosphere.

A successful feasibility assessment, to which ARENA funded $11.3 million (USD $7.8 million), guided the decision to proceed with the technology.

Titled “Roadmap for Decarbonising Australian Alumina Refining,” the report found that deploying four technologies could cut emissions at Australian alumina refineries by as much as 98 per cent.

Among these four technologies, MVR tackles the most emissions-intensive stage of refining.

In particular, MVR employs electricity to pressurise waste steam, thereby recycling water and thermal energy, making the upfront costs of MVR even cheaper than conventional evaporation.

Director of Alcoa’s Refinery of the Future, Darren Shanahan, says Alcoa is pleased that the preliminary analysis indicates that MVR adoption is both technically and economically possible.

“With the current alumina and aluminium industries being major fossil fuel energy users and greenhouse gas emitters, decarbonisation is a critical focus area for operators, governments and broader society,” he said.

Shanahan added that MVR might make a significant contribution to the decarbonisation of the alumina industry in Australia and around the world and considerably reduce water use in alumina refinery processes.

The Wagerup construction is set to begin in mid-2023, with the MVR system expected to be operational in 2024.