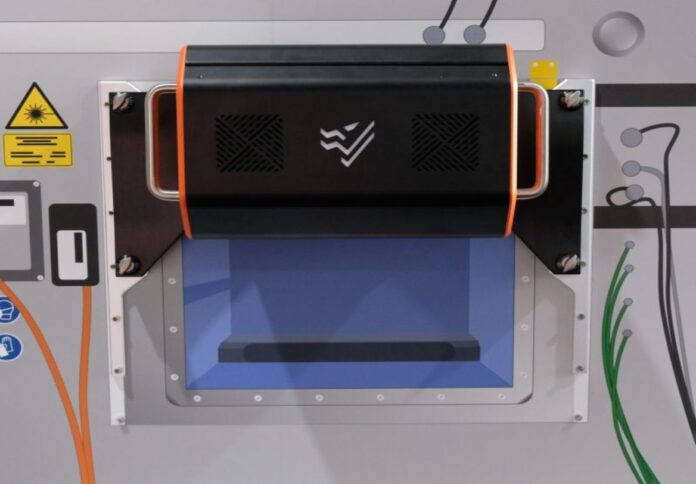

Additive Assurance, a provider of in-process quality assurance for metal additive manufacturing (AM), has introduced its AMiRIS-LF (Large Format) system in an effort to improve production scale quality assurance for metal AM.

The Melbourne-based firm said the AMiRIS-LF represents the latest chapter in its ongoing commitment to quality assurance in metal additive manufacturing.

Tailored for large format Laser Powder Bed Fusion (L-PBF) systems with platforms of 400mm or larger, this system brings Additive Assurance’s unique process monitoring and QA solution to larger production systems, with a focus on aerospace, defence and energy applications.

In addition to AMiRIS-LF, the company said it has successfully broadened the reach of its standard AMiRIS solution, first introduced in 2021.

To date, the standard AMiRIS supports eight different L-PBF machine types, showcasing Additive Assurance’s dedication to universal quality assurance solutions for all L-PBF systems.

Marten Jurg, the co-founder and CEO of Additive Assurance, emphasised that AMiRIS-LF signifies their dedication to innovation and quality in AM.

“AMiRIS LF is a reflection of our commitment to innovation and quality in additive manufacturing, taking us a step closer to our mission of creating a universal quality assurance solution that works seamlessly across different machine brands,” he explained.

In a bid to showcase the capabilities and potential of AMiRIS-LF, Additive Assurance extends an invitation to attendees to visit their exhibit at Formnext 2023.

Formnext is a globally recognised trade fair dedicated to additive manufacturing and modern industrial production, scheduled to occur in Frankfurt from 7 to 10 November 2023.

Additive Assurance’s exhibit will take place in the Victorian Government Pavilion, specifically in Hall 12.0 at B59.