Laser technology manufacturer ActionLaser is entering the global market for plastic recycling machinery thanks to a collaborative project backed by the Advanced Manufacturing Growth Centre (AMGC) and the federal government.

The project, which received $558,500 in co-funding through AMGC’s Commercialisation Fund, has transformed ActionLaser’s expertise in laser drilling filtration into melt filtration systems that will serve as the core of any plastic recycling machine.

The company has launched the MeltFilter brand, which is now being sold in the global market and has vast potential among recyclers who have been limited to one single supplier for a vital, highly complex consumable.

Bevan Rashford, ActionLaser’s CEO and the original researcher behind the MeltFilter technology, said the AMGC-backed project has helped the company increase its sales, hire more staff, and export nearly 80 per cent of ActionLaser products.

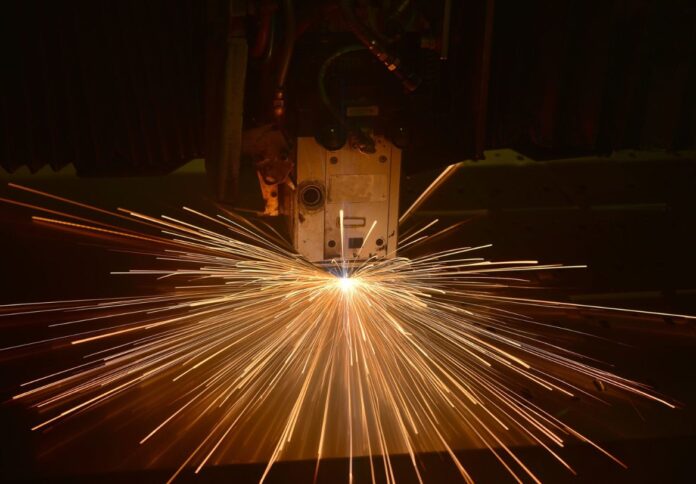

“Precision is in our DNA and we are very good at drilling small holes with lasers. But applying this to world-class melt filters involves not just precise laser drilling techniques, but access to the correct steels, various kinds of specialised hardening processes, mastery of some very complex design challenges, and high-level software and automation to ensure you can do it all competitively,” said Steve Greer, global manager for MeltFilter.

The project leveraged the expertise of Senarc Services, which is run by ActionLase co-founder and former CSIRO industrial laser group leader Ken Crane, in collaboration with stage engineering firm Simple Motion.

Established in 1998 by researchers of laser drilling technology from CSIRO, ActionLaser has been focused on manufacturing next-generation perforated centrifuge screens for Australian sugar processors before branching into equipment for other industries.

The company has supplied precise, laser-drilled filtration screens for various industries, including food and beverage, mineral and chemical processing, agriculture, water, and recycling.

“ActionLaser is the kind of manufacturer that reminds you of what works, and what can be achieved in Australia by commercialising and exporting our great ideas and products,” said Jens Goennemann, managing director of AMGC.

“Founded with the specific aim of meeting a global need, ActionLaser focussed on solving that problem, basing its competitiveness on technical superiority rather than cost, and willing to invest in difficult R&D programs to progress,” Goennemann added.

Heat Treatment Australia, a thermal hardening specialist, was also involved in the project, serving as an important partner in ActionLaser’s supply chain by providing core hardening technologies.

ActionLaser is planning to boost its revenue by 25 per cent in 2024, with the same amount the following years from new business, and to hire technologists with STEM backgrounds in the process.