Researchers from RMIT University and the National Institute of Technology, Warangal (India) have developed an eco-friendly way of making graphene that also promises to significantly drive down the cost of producing this ultra thin and strong material.

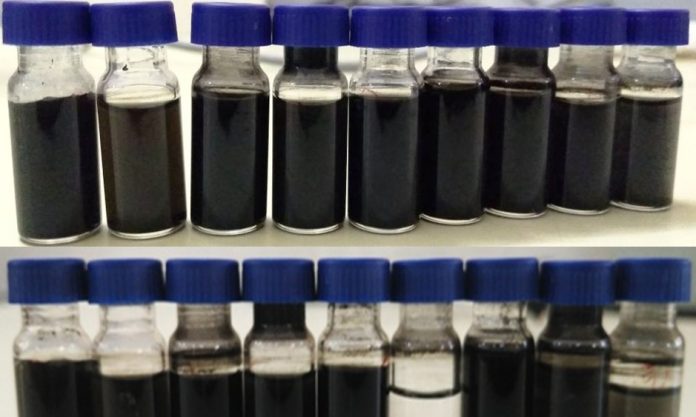

The new method of producing graphene uses Eucalyptus bark extract as raw material, which makes it significantly cheaper and more sustainable than current synthesis methods.

RMIT lead researcher, Distinguished Professor Suresh Bhargava, said the new method could reduce the cost of making graphenee from US$100 per gram to a staggering US$0.5 per gram.

“Eucalyptus bark extract has never been used to synthesise graphene sheets before and we are thrilled to find that it not only works, it’s in fact a superior method, both in terms of safety and overall cost,” Professor Bhargava said.

“Our approach could bring down the cost of making graphene from around US$100 per gram to just 50 cents, increasing it availability to industries globally and enabling the development of an array of vital new technologies.”

Professor Vishnu Shanker from the National Institute of Technology, Warangal, said the method avoids the use of toxic reagents that are dangerous to both people, paving the way for the application of graphene not only for electronic devices but also biocompatible materials.

“Working collaboratively with RMIT’s Centre for Advanced Materials and Industrial Chemistry we’re harnessing the power of collective intelligence to make a lot more useful discoveries,” he said.

Professor Bhargava said the ‘green’ graphene produced using this method matched the quality and performance characteristics of traditionally-produced graphene when tested in the application of a supercapacitor.

“Graphene is a remarkable material with great potential in many applications due to its chemical and physical properties and there’s a growing demand for economical and environmentally friendly large-scale production,” he concluded.