Researchers at Georgia Tech have developed a 3D-printed, bioresorbable heart valve designed to promote tissue regeneration, potentially reducing the need for repeated surgeries among patients with heart valve disease.

The innovation, led by faculty members Lakshmi Prasad Dasi and Scott Hollister, aims to provide a long-term, patient-specific solution to a condition that affects over five million people in the US annually.

According to researchers, heart valve disease disrupts blood flow when a valve is severely damaged due to birth defects, aging, or lifestyle factors.

Current treatment options, including valve replacement and repair, often necessitate multiple surgeries over a patient’s lifetime.

Most replacement valves, typically made from animal tissue, last only 10 to 15 years before requiring replacement, making pediatric cases particularly challenging.

“This technology is very different from most existing heart valves, and we believe it represents a paradigm shift,” said Dasi, the Rozelle Vanda Wesley Professor in Biomedical Engineering (BME) at Georgia Tech and Emory University.

“We are moving away from using animal tissue devices that don’t last and aren’t sustainable, and into a new era where a heart valve can regenerate inside the patient.”

Hollister, who holds the Patsy and Alan Dorris Chair in Pediatric Technology, highlighted the significance of the advancement for younger patients.

“In pediatrics, one of the biggest challenges is that kids grow, and their heart valves change size over time. Because of this, children must undergo multiple surgeries to repair their valves. With this new technology, the patient can potentially grow new valve tissue and not have to worry about multiple replacements in the future.”

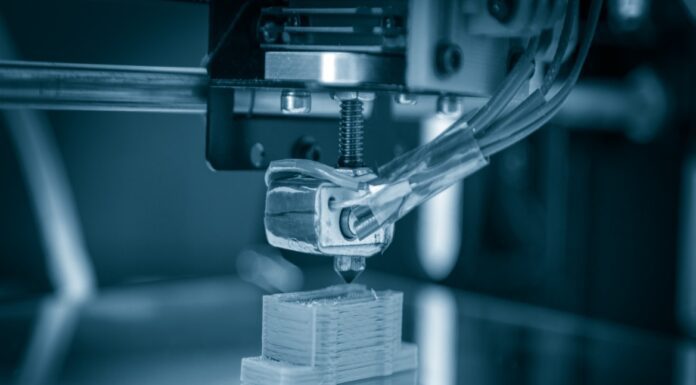

The new heart valve is 3D-printed from poly(glycerol dodecanedioate), a biocompatible material that can be folded and inserted via catheter rather than requiring open-heart surgery.

Upon reaching body temperature, it returns to its original shape and stimulates the body to generate new tissue. The original device dissolves within months, leaving behind a fully functional, regenerated valve.

While bioresorbable implants and 3D-printed valves exist separately, the Georgia Tech team is the first to integrate both technologies.

“From the start, the vision was to move away from the one-size-fits-most approach to heart valve design and toward a patient-specific implant that can outlast current devices,” said Sanchita Bhat, a research scientist in Dasi’s lab.

The project required extensive material testing and prototype refinement. Ph.D. student Srujana Joshi has played a key role in analyzing the valve’s design and performance.

“It takes a lot of fine-tuning and optimization to arrive at the right design, material, and manufacturing parameters that work,” Joshi said.

The team is currently evaluating the valve’s physical durability using computational models and benchtop studies, including simulations that replicate real heart conditions.

Despite its promise, the device must undergo rigorous testing and regulatory approvals before it can be widely used.

The researchers believe their approach could eventually be applied beyond pediatric patients. “The hope is that we will start with children who have no other treatment options,” Dasi said.

“Then we hope to show, over time, that there’s no reason why all valves shouldn’t be made this way.”

The project has received funding from the National Institutes of Health, with contributions from additional researchers, including Harsha Ramaraju, Ryan Akman, Adam Verga, David Rozen, Satheesh Kumar Harikrishnan, and Hieu Bui.