A collaboration between Idaho National Laboratory (INL) and Oak Ridge National Laboratory (ORNL) has accelerated the inspection process for additively manufactured nuclear components and is now expanding to evaluate nuclear fuels.

The partnership leverages an ORNL-developed algorithm to detect flaws in materials, reducing inspection time and enhancing worker safety, ORNL said in a media release.

The algorithm, named Simurgh, utilises realistic training data and physics-based simulations to reconstruct accurate images with fewer scans, cutting inspection times for dense materials by a factor of 12.

This advancement is critical in qualifying materials and technologies for next-generation nuclear reactors, traditionally a decades-long process.

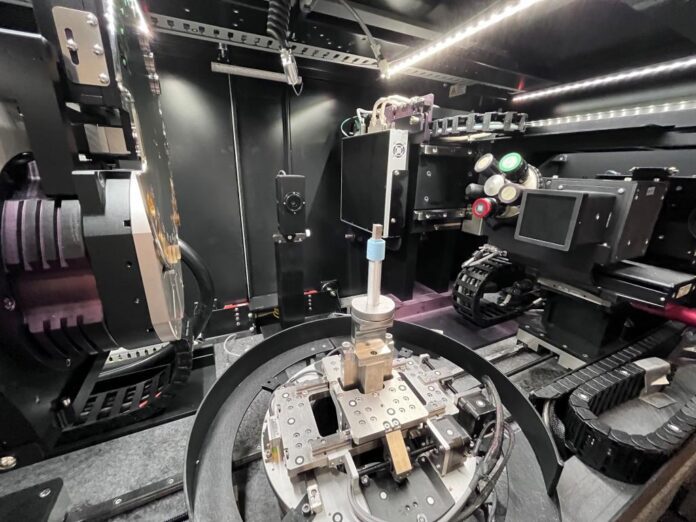

Researchers are now adapting Simurgh to inspect irradiated nuclear fuel casings at INL, further streamlining material evaluations.

Bill Chuirazzi, leader of INL’s Diffraction and Imaging group, highlighted the potential of the technology to reduce radioactive fuel scan times by 90 per cent, expediting material development and ensuring safety.

The collaboration emerged from INL’s need to analyze large data sets of 3D-printed samples efficiently.

By integrating Simurgh, researchers reduced scan times significantly, enabling rapid feedback and improving manufacturing processes.

The technology’s application extends beyond current projects, with potential uses in advanced reactor designs and other high-precision fields.

ORNL’s Manufacturing Demonstration Facility Director, Ryan Dehoff, emphasised the technology’s reliability, which meets the demands of the nuclear industry.

Simurgh’s evolving capabilities aim to achieve broader impacts, from inspecting TRISO nuclear fuels to evaluating 3D-printed components exposed to radiation.