Titomic, a global leader in cold spray technology, has been invited to participate in DNV’s prestigious Joint Industry Project (JIP), ProGRAM.

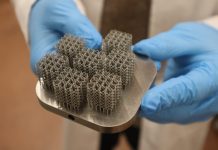

This research and development initiative aims to establish standardised practices for additive manufacturing in the oil and gas sector, the company said in an ASX announcement.

According to TItomic, the ProGRAM initiative represents a major opportunity for Titomic to advance the commercialisation of its cold spray technology within an industry that has long struggled with challenges such as corrosion, wear, and part failure.

The collaboration between Titomic and DNV will focus on setting new standards for manufacturing and repairing equipment using cold spray, streamlining specifications for common parts, materials, and specific use cases.

Initial efforts will target qualification standards for manufacturing structural and machine parts from Alloy 625 and subsea components in low-alloy carbon steel.

The project will also explore using cold spray technology for repair work, helping to make production processes more efficient and sustainable.

DNV provides testing, certification, and technical advisory services for the energy sector, including oil, gas, and renewables.

Through its partnership with DNV, Titomic’s cold spray technology is poised to gain broader exposure in the energy industry, solidifying its position as a leader in innovative repair, coating, and additive manufacturing solutions, the company noted.

By participating in the ProGRAM initiative, Titomic said it aims to accelerate the adoption of cold spray technology, offering the oil and gas sector a more sustainable and effective approach to manufacturing and equipment maintenance.

For more information, visit Titomic’s official website.