Monash University researchers have revealed that manufacturing businesses adopting circular economy (CE) strategies can significantly reduce their waste, cutting it by up to 65 per cent.

This finding comes as Australia’s manufacturing sector faces scrutiny for its substantial contribution to waste generation, with nearly 13 million tonnes of waste produced nationwide each year, the university said in a news release.

In Victoria alone, the manufacturing industry accounts for 39 per cent of the state’s total waste.

On average, the sector generates 4,350 kilograms of waste per full-time-equivalent (FTE) employee annually, leading to nearly 500,000 tonnes of waste per year in the southeast Melbourne region.

In response to these challenges, Victoria’s manufacturing industry has partnered with Monash Business School’s Department of Management to develop and implement strategies aimed at improving resource efficiency, minimising waste, and mitigating the environmental impacts of production.

According to the university, these efforts are centred around the adoption of CE principles and practices.

The three-year project, led by Professor Amrik Sohal from the Department of Management, involved collaboration with Victorian manufacturers across various sectors, including plastics, textiles, general engineering, and food.

The initiative also included input from industry associations and local government representatives. The project aimed to raise awareness, build capability, and support the transition to a CE within the industry.

Professor Sohal’s team conducted interviews with 25 leading businesses that have implemented CE practices to gather insights and best practices.

These findings were then shared with the broader manufacturing community through workshops and seminars designed to educate and inspire change.

A post-workshop survey revealed that participants’ attitudes and behaviours shifted significantly after learning about the economic and cost-saving benefits of CE practices.

This shift underscores the potential for CE strategies to transform the manufacturing sector.

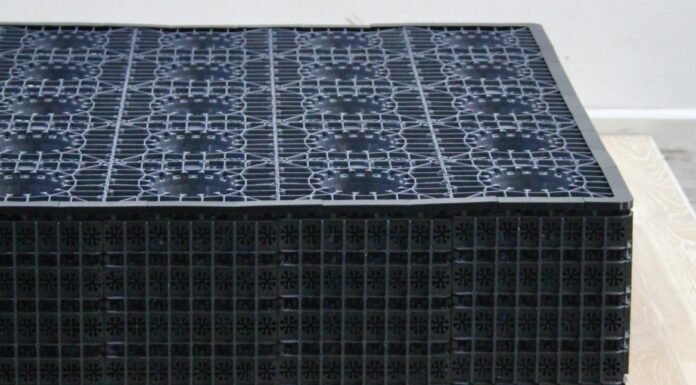

One of the businesses highlighted in the study is Jardan, an Australian family-owned high-end furniture company.

Jardan reported a 65 per cent reduction in manufacturing waste after implementing CE strategies.

The company emphasises sustainability throughout its product lifecycle, sourcing over 75 per cent of its materials from Australian suppliers, designing products for longevity, and reducing energy consumption by 17 per cent.

Professor Sohal noted that cases like Jardan demonstrate the potential outcomes when CE practices are actively embraced.

“CE focuses on optimising resource utilisation, grounded in the belief that the economic system already possesses sufficient resources,” he said.

The professor added, “By enhancing resource efficiency, the goal is to decouple the economic system from resource extraction and waste generation, while extending the lifespan of resources to their maximum potential.”

Based on the experiences of the leading businesses involved in the study, the researchers suggest several strategies to help manufacturers adopt CE practices:

- Incorporate circularity into product design by using alternative or recycled materials.

- Adopt a systems approach by integrating circularity throughout the entire supply chain.

- Ensure the financial viability of the business model to sustain CE practices.

- Be transparent and genuine in CE efforts to build trust and credibility.

- Educate stakeholders on the value of their contributions to CE initiatives.

Create networks of like-minded communities by collaborating with others and sharing best-practice knowledge.