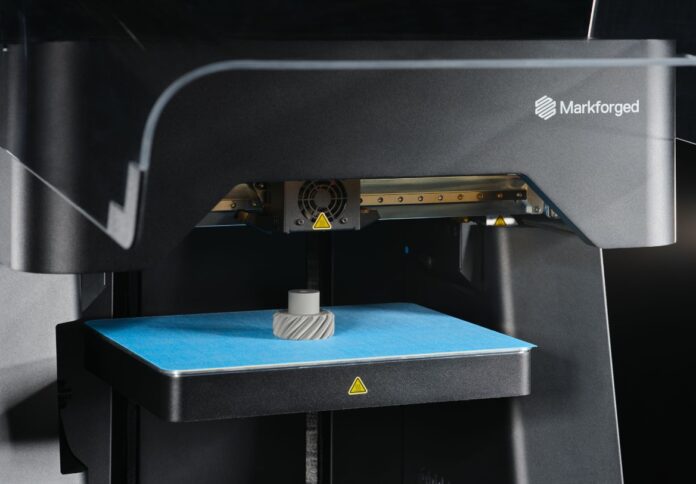

Markforged has launched the FX10 Metal Kit, which upgrades the FX10 3D printer to become what it claims as the first industrial model capable of printing both metal filaments and composites with continuous fibre reinforcement.

According to the firm, the FX10 Metal Kit enables users to seamlessly transition between metal and composite printing, addressing a long-standing gap in the 3D printing market.

According to Shai Terem, CEO of Markforged, “Customers no longer have to choose between a metal and a composite printer. Years of R&D investment and field experience have come together to provide an all-in-one solution for 3D printing to provide immediate return on investment once installed on a factory floor.”

Terem emphasised that the FX10 enhances the efficiency and productivity of other factory floor equipment, potentially reducing operational disruptions.

Originally launched in November 2023 as a composite-only printer, the FX10 has been well-received for its versatility and performance.

The addition of the Metal Kit enhances the machine’s functionality, allowing it to print in both metal and composite materials.

The FX10 Metal Kit includes a new metal-specific print head, material feed tubes, routing back, and dual pre-extruders.

According to Markforged, the conversion process between metal and composite printing takes approximately 15 minutes.

The company has also introduced a new 316L stainless steel filament, with future plans to support additional metal filaments, including 17-4PH.

“We designed the FX10 to be a modular platform,” Terem explained. “This allows us to release new innovations and upgrades without customers having to purchase a new printer every year.”

The FX10 Metal Kit features the 2nd Generation Metal FFF engine, which offers faster print speeds compared to previous models.

Coupled with a print volume twice as large as earlier Markforged metal printers, the new system promises enhanced productivity.

The metal prints are created using a combination of metal filament and a ceramic release filament, which facilitates easy removal of support structures.

Post-processing includes washing and sintering with Markforged’s Wash-1 and Sinter-2 solutions, and Eiger, Markforged’s slicer and print management software, automates the process, including scaling parts for shrinkage during sintering.

The FX10 is part of Markforged’s Digital Forge, an additive manufacturing platform designed to integrate seamlessly into existing manufacturing environments.

The Digital Forge enables users to manage and monitor their printing operations from a centralised location and share parts across their organization.

Markforged will showcase the FX10 Metal Kit at the International Manufacturing Technology Show (IMTS) in Chicago, Illinois, from 9 to 14 September.

Attendees can visit booth 432305 to see live demonstrations of the FX10 printing both continuous fiber-reinforced composites and metal.

For more information on the FX10 Metal Kit and Markforged’s suite of 3D printing solutions, visit Markforged’s website.