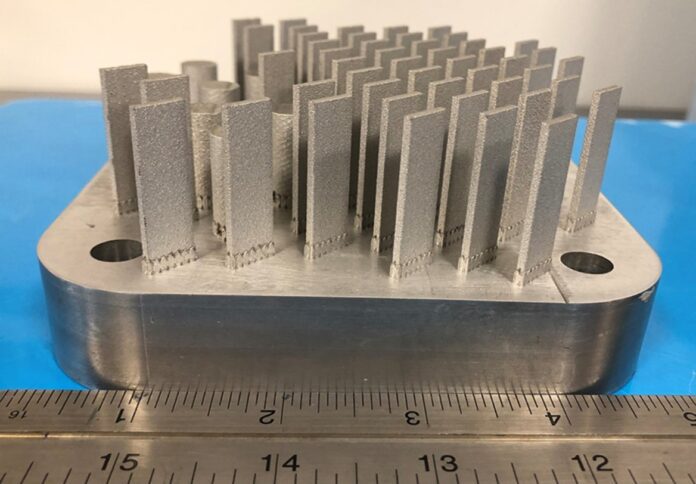

Purdue University material engineers have developed a process to create ultrahigh-strength aluminium alloys suitable for additive manufacturing by utilising their plastic deformability.

This innovative process, which is currently patent-pending, aims to revolutionise industries reliant on high-strength, lightweight materials, the researchers said in a news release.

Haiyan Wang, the Basil S. Turner Professor of Engineering, and Xinghang Zhang, a professor in Purdue’s School of Materials Engineering, lead the pioneering research team.

They are joined by Anyu Shang, a graduate student in materials engineering. Together, they have introduced transition metals such as cobalt, iron, nickel, and titanium into aluminium through nanoscale, laminated, deformable intermetallics.

In particular, Purdue researchers have produced intermetallic-strengthened aluminium alloys by incorporating transition metals such as cobalt, iron, nickel, and titanium.

These metals have traditionally been avoided in aluminium alloy manufacturing due to their brittleness at room temperature.

“These intermetallics have crystal structures with low symmetry and are known to be brittle at room temperature,” Shang said.

Shang continued, “But our method forms the transitional metal elements into colonies of nanoscale, intermetallics lamellae that aggregate into fine rosettes. The nanolaminated rosettes can largely suppress the brittle nature of intermetallics.”

Wang added, “The heterogeneous microstructures contain hard nanoscale intermetallics and a coarse-grain aluminium matrix, which induces significant back stress that can improve the work hardening ability of metallic materials. Additive manufacturing using a laser can enable rapid melting and quenching, introducing nanoscale intermetallics and their nanolaminates.”

The research team conducted extensive testing to validate their method, including macroscale compression tests, micropillar compression tests, and post-deformation analyses on the newly created aluminium alloys.

“During the macroscale tests, the alloys revealed a combination of prominent plastic deformability and high strength, more than 900 megapascals. The micropillar tests displayed significant back stress in all regions, and certain regions had flow stresses exceeding a gigapascal,” Shang reported.

Shang continued, “Post-deformation analyses revealed that, in addition to abundant dislocation activities in the aluminum alloy matrix, complex dislocation structures and stacking faults formed in monoclinic Al9Co2-type brittle intermetallics.”

“Our work shows that the proper introduction of heterogenous microstructures and nanoscale medium-entropy intermetallics offers an alternative solution to design ultrastrong, deformable aluminium alloys via additive manufacturing,” Zhang stated.

“These alloys improve upon traditional ones that are either ultrastrong or highly deformable, but not both.”

Wang and Zhang have disclosed their innovation to the Purdue Innovates Office of Technology Commercialization, which has filed for a patent from the U.S. Patent and Trademark Office to protect the intellectual property.

The research has been published in the peer-reviewed journal Nature Communications, with support from the National Science Foundation and the US Office of Naval Research.