Global additive manufacturing company SPEE3D has introduced a new material for its patented Cold Spray Additive Manufacturing (CSAM) technology.

The company announced the commercial availability of Nickel Aluminium Bronze Expeditionary (NAB Expeditionary), a material designed for field deployment that enables the production of parts in hours rather than days.

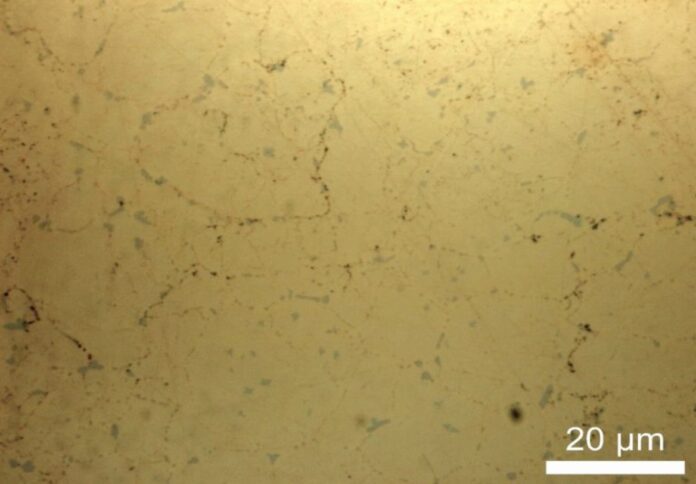

According to the firm, NAB Expeditionary is a high-strength, corrosion-resistant alloy known for its lubricity, resistance to cavitation damage, and stress corrosion cracking.

Composed mainly of copper, with significant amounts of aluminium, nickel, and iron, this material is particularly suitable for maritime applications due to its strength and corrosion resistance in seawater and other harsh environments.

It is also relevant for the defence, oil and gas, and mining industries, with parts that can be produced and delivered in less than 24 hours.

SPEE3D said it will be attending the RAPID + TCT Conference, North America’s largest manufacturing event, from 25 to 27 June at the Los Angeles Convention Center, booth #2439.

The company will demonstrate on-site printing of NAB Expeditionary parts, allowing attendees to witness the capabilities of its WarpSPEE3D printer and CSAM technology, which provides rapid and cost-effective metal printing solutions to address supply chain challenges across various industries.

Additionally, SPEE3D will showcase parts created by the newly introduced TitanSPEE3D, a large-format metal printer.

With a build volume of 2.4 meters in diameter by 1 meter tall, a maximum printed part weight of 2,000 kilograms, and a 4.3m x 4.3m footprint, TitanSPEE3D offers new possibilities in CSAM by enabling the quick, sustainable, and cost-effective production of large, high-quality metal parts, bypassing traditional cast molding methods.

“Each year, we look forward to participating at RAPID + TCT and are thrilled to print parts once again on-site, showcasing why our unique Cold Spray Additive Manufacturing technology is ideal for various industries requiring large-scale metal parts printed quickly, easily, and sustainably,” said Byron Kennedy, CEO of SPEE3D.

He added, “I’m excited to be here in Los Angeles and meet with our partners and potential clients, showcasing Nickel Aluminum Bronze Expeditionary and discussing our large format printer, TitanSPEE3D.”