Bosch, a pioneer in automation solutions, has partnered with RayGen, an innovator in solar and long-duration storage technologies, to expedite the deployment of its state-of-the-art concentrated solar photovoltaic (PV) system.

This collaboration highlights the crucial role of automation in advancing modern energy solutions, Bosch said in a media release.

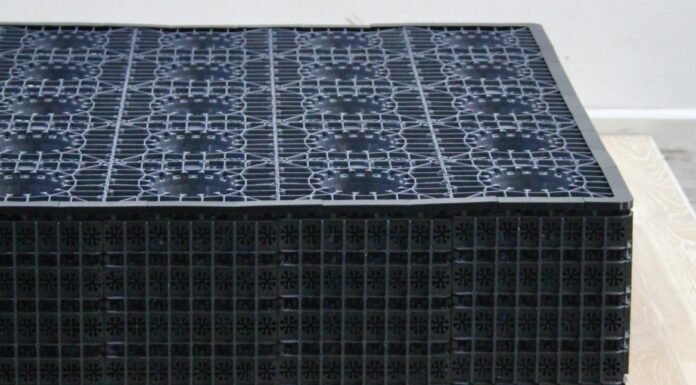

The project focuses on the assembly of heliostats—mirrors used to focus sunlight—which are vital components of the concentrated solar PV system.

Bosch said these heliostats are designed to track the sun, optimising solar energy capture throughout the day.

After rigorous field testing, the assembly process will be deployed on-site at RayGen’s first utility-scale project.

Bosch Australia Manufacturing Solutions (BAMS) automation engineering specialists have designed a highly automated production line for this purpose.

“With this project, RayGen is further advancing Australia’s leading position in the application of renewable technologies. We are excited to be a part of it,” said Gavin Smith, President Bosch Oceania.

BAMS’ cutting-edge automation capabilities are key to making the assembly process faster and more cost-effective. The project aims to assemble a heliostat every three minutes, demonstrating the efficiency of their system.

“Automating our assembly processes with the best industry experts is essential for our mission to scale RayGen’s technology to a global customer base,” said RayGen Chief Executive Officer, Richard Payne.

He added, “We’re delighted to partner with Bosch Australia Manufacturing Solutions and we look forward to working more closely with the Bosch team.”

The heliostats, each measuring approximately 4×5 meters, consist of eight individual mirror panels that must be assembled to precise tolerances to maximise energy production.

According to Bosch, the automation project is scheduled for deployment by the end of the year.