RMIT University and Macedon Ranges Shire Council have joined forces to pioneer a trial of coffee concrete footpaths, potentially bringing freshly brewed coffee-infused pavements to local streets for the first time.

Several upcoming infrastructure projects around Victoria, Australia, will also utilise spent coffee grounds, transforming this waste into a valuable construction resource, the university stated in a news release.

In particular, RMIT has partnered with Australian-owned BildGroup to deliver these circular-economy projects, addressing the environmental impact of organic waste, which contributes 3 per cent of greenhouse gas emissions when sent to landfill.

Dr Rajeev Roychand and his colleagues at RMIT have developed a technique to make concrete 30 per cent stronger by using coffee biochar, produced through a low-energy process at 350 degrees Celsius.

This innovation allows spent coffee grounds to have a “double shot” at life, reducing landfill waste.

The team employs similar methods to convert other organic waste, such as wood chips, into biochar, which also enhances concrete strength.

Australia generates 75 million kilograms of coffee waste annually, most of which ends up in landfills. However, this waste could replace up to 655 million kilograms of sand in concrete.

Globally, 10 billion kilograms of spent coffee could substitute 90 billion kilograms of sand in concrete.

Roychand explained that coffee and wood-chip biochar can replace a portion of the river sand used in concrete.

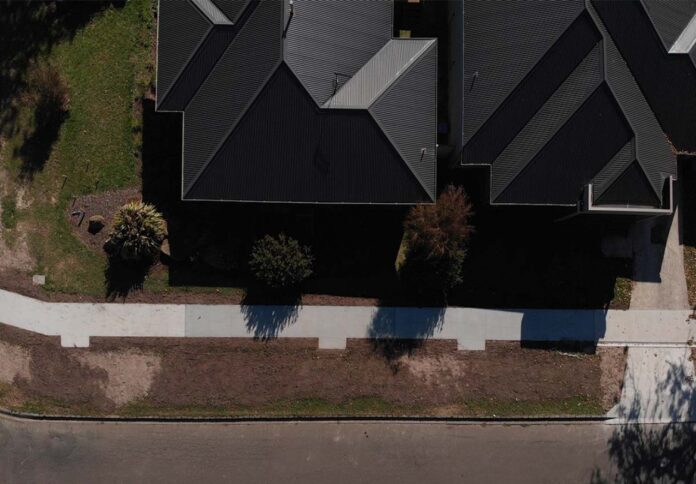

The team is collaborating with the council to trial both types of biochar in concrete footpaths in Gisborne.

“It’s very exciting to see this world-first trial of our coffee and wood-based biochar in these footpaths in collaboration with Macedon Ranges Shire Council,” said Roychand from the School of Engineering.

He added, “Sand is getting scarce over time, and this waste can replace up to 15% of the sand in concrete.”

Shane Walden, the council’s Director of Assets and Operations, expressed enthusiasm for the project, noting that it would have tangible environmental and sustainability benefits for the community.

“This not only helps improve the knowledge level of our contractors and our staff, but it also has lots of other benefits and benefits that are important to our community,” Walden asserted.

The researchers will assess the performance of the concrete in these trial footpaths in Gisborne to support further deployment of this innovation.

“We are currently working in the supply chain sector to make this research a mainstream product for commercial applications, and we’re expanding this into various forms of organic waste,” Roychand said.

The unique properties of biochar from different organic materials can enhance concrete in multiple ways, potentially offering cost savings for construction companies by reducing the required cement content.

The trial with Macedon Ranges Shire Council did not initially reduce the amount of cement used in footpath projects, but the RMIT team plans to experiment with less cement.

The project has received support from ARUP Australia Pty Ltd, Earth Systems Pty Ltd, and RMIT University, including the Strategic Capability Deployment Fund and various research facilities.