As innovations transform today’s global industrial landscape, it is becoming more apparent to Australian manufacturers that they can no longer afford to be caught off guard by emerging trends or technological breakthroughs. The ability to adapt to manufacturing’s “next big thing” is no longer a competitive advantage but a survival necessity.

To remain competitive, profitable, and sustainable, manufacturers must learn how to navigate reliable supply chains, fluctuating economic conditions, and intense global competition.

A whitepaper published by Global Shop Solutions highlighted the pivotal changes for Australian manufacturers looking to thrive now and well into the future.

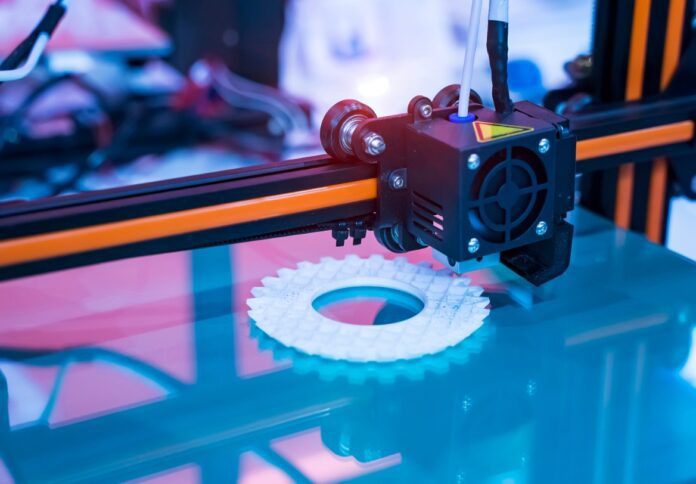

Increased automation

Previously, when the market environment was more stable, manufacturers could focus on optimising internal factors, such as workforce efficiency, production processes, and business models, to drive success. They zeroed in on enhancing operations and streamlining workflows in a bid to boost productivity and cut costs.

As today’s industrial landscape demands a more agile and comprehensive approach, manufacturers are faced with the need to shift their focus beyond internal optimisation and include rapid technological changes, such as artificial intelligence and Internet of Things.

However, Global Shop Solutions’ whitepaper warned against adopting automation technologies simply because they are the latest trend. It is crucial to develop a strategy that aligns automation with the broader business and operational goals of the organisation.

Making smarter decisions

Business intelligence, also known as big data, provides manufacturers with a comprehensive picture of their operations, from supply chain logistics to customer preferences. Access to actionable information enables business leaders to anticipate market trends, adapt to customers more swiftly, and optimise their operations for enhanced productivity and reduced waste.

This kind of analysis has become increasingly sophisticated thanks in no small part to enhancements in enterprise resource planning (ERP) systems. ERP providers continually add new features and functionalities that enable manufacturers to customize how they view and leverage big data. These advancements include tailored ERP solutions, the integration of dashboards, and data flow automation.

Prioritising environmental responsibility

As the world’s consumers gain more environmental awareness and governments impose stricter regulations, sustainability is becoming a key focus for the Australian manufacturing sector.

This push towards sustainable manufacturing involves integrating practices that minimise waste, maximise resource efficiency, and develop products with their entire lifecycle in mind.

Adopting sustainable practices in manufacturing can be challenging but the benefits are substantial. Manufacturers who successfully reduce their carbon footprint enhance their brand and attract customers who value sustainability.

Fostering innovation within the manufacturing industry not only prepares manufacturers for the immediate challenges of a rapidly evolving market; it also positions Australia as a leader in a sustainable and technologically advanced manufacturing future.

To learn more about the “5 Changes Manufacturers are Making Today and for Tomorrow,” visit globalshopsolutions.com.