Australia’s premier tyre recycling company Tyrecycle has inaugurated its latest state-of-the-art facility in East Rockingham, Perth.

The official opening ceremony was graced by Reece Whitby, Minister for Energy, Environment, and Climate Action of Western Australia, and Madeleine King, Federal Minister for Resources.

Situated 40 kilometres south of Perth, the company said this new hub represents a ‘significant advancement’ in national tyre processing capabilities.

With an investment of $15 million, a portion of which was secured through the jointly supported State and Federal Government’s Recycling Modernisation Fund (RMF), the facility boasts an annual processing capacity of 42,000 tonnes of tyres.

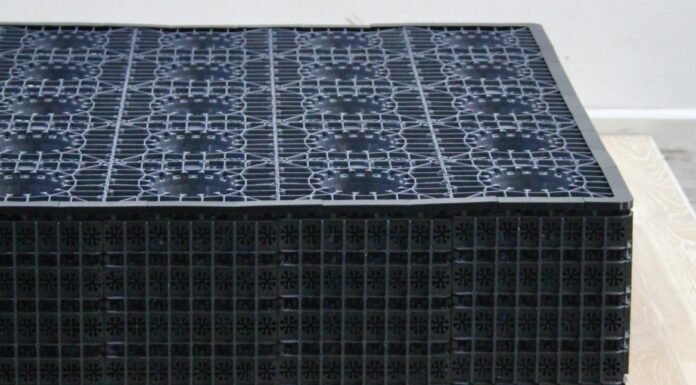

Additionally, it will generate 7,000 tonnes of crumbed rubber annually, crucial for road construction projects across Western Australia.

Excess crumbed rubber will find its way to international markets like Japan, where it will serve as tyre-derived fuel (TDF), replacing coal.

Tyrecycle has cemented strategic five-year offtake agreements with Japanese industrial giants, Daicel Corporation and Nippon Paper Group, highlighting the company’s commitment to global market expansion and sustainable waste management practices.

As the largest and most sophisticated tyre recycling plant in Australia, the new facility is set to bolster Tyrecycle’s national presence, complementing its network of seven tyre processing plants.

Acting as the primary processing plant for Perth’s car, truck, and bus tyres, the East Rockingham facility will also function as a secondary processing plant for Tyrecycle’s planned Port Hedland operations, aimed at addressing the substantial OTR waste generated by the mining industry.

With both facilities slated to commence operations this year, Western Australia is poised to achieve greater self-sufficiency in rubber waste management, setting a benchmark for sustainable practices nationwide.

Tyrecycle CEO Jim Fairweather expressed his enthusiasm, stating, “There’s no other facility like this in Australia in terms of versatility, scale, and excellence. Whether it’s the plant configuration, the quality of equipment, or the production capability, this facility represents best practice across the board.”

Fairweather added, “This plant is the most flexible and technologically advanced in Tyrecycle’s growing portfolio. Importantly, it will allow us to drive as much product back into the Western Australia market and domestic sales as physically possible.”