Article by James Robinson, Vice President of Services for Asia Pacific at SYSPRO

In the dynamic manufacturing sector, where competition is intensifying and innovation is recognised as a key differentiator, manufacturers are always looking to enhance operational efficiency, minimise costs and elevate product quality.

Whilst tackling this challenge, the role of embedded analytics integrated within manufacturing environments through an Enterprise Resource Planning (ERP) system combined with the Internet of Things (IoT), has emerged as a route to achieving digital transformation.

How can manufacturers utilise embedded analytics?

At its core, embedded analytics is about integrating analytical capabilities directly into ERP and Manufacturing Operations Management (MOM) systems. This integration brings data analytics into the daily workflow of users, enabling real-time insights without necessitating the use of external tools or navigating through complex processes.

Enabling data-driven decision-making on the shop floor, manufacturers can leverage embedded analytics for scalable, comprehensive insights. For manufacturers, this means the ability to make informed decisions quickly, adapt to market fluctuations and meet customer demands with extraordinary agility; enabling them to navigate the complexities of modern manufacturing.

The synergy between embedded analytics and ERP systems

The integration of embedded analytics with ERP systems represents a significant leap forward for manufacturers. ERP systems, the backbone of many manufacturing operations, oversee various aspects of an organisation, including inventory management, production scheduling, supply chain logistics and financials.

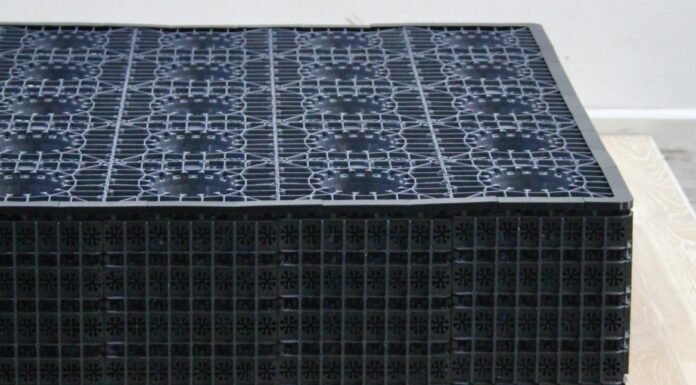

By embedding analytics directly into these systems, manufacturers unlock a wealth of real-time data and insights, for example, it can manage inventory in the warehouse in real-time using IoT sensors to monitor and track incoming and outgoing goods. Individual items including cases, pallets, containers and vehicles will continuously update their location and movement, due to auto-identification tags that are tied to GPS-enabled connections.

These advanced capabilities will enable manufacturing companies to enhance the customer user experience and improve service delivery by connecting the warehouse to e-commerce platforms.

Data-driven decision-making is enhancing operational efficiency

Embedded analytics transforms ERP systems from repositories of transactional data to dynamic engines of insight. Manufacturers gain a 360-degree view of their operations, from the shop floor to the customer’s door. This visibility enables them to identify bottlenecks, predict maintenance needs and optimise production schedules, all in real time.

For instance, pre-built dashboards and reports can highlight inefficiencies in the supply chain, while self-service analytics capabilities empower managers to explore data and derive actionable insights, enabling a culture of continuous improvement.

The integration of embedded analytics into ERP systems enables the monitoring of production processes and supply chain operations in real-time. This capability is crucial for detecting issues as they arise and initiating corrective measures promptly.

By analysing data from IoT devices and sensors embedded in manufacturing equipment, manufacturers can predict failures before they occur, schedule maintenance proactively and virtually eliminate downtime. This predictive approach to maintenance uses embedded analytics to enhance operational efficiency and improve productivity.

Facilitating collaboration and innovation

Embedded analytics also plays a pivotal role in breaking down information silos within manufacturing businesses. By providing a centralised platform delivering data and insights, it encourages cross-departmental collaboration. Teams can share findings, align strategies and work towards common goals with a unified view of data.

This collaborative environment is conducive to innovation, as insights gathered from one department, such as operations can inspire new approaches in another, such as Training and Development or Human Resources.

The role of IoT in amplifying embedded analytics

The rapid growth of IoT has significantly increased the volume and variety of data available for analysis. Manufacturing equipment and products embedded with sensors generate a continuous stream of data, offering insights into every aspect of the manufacturing process and product lifecycle.

When IoT data is analysed through embedded analytics within ERP systems, manufacturers can achieve a level of granularity in their insights that was previously unachievable. This depth of analysis supports more nuanced decision-making, enabling manufacturers to fine-tune their operations for optimal performance and customer satisfaction.

Conclusion

With IoT working to collect vast amounts of data, manufacturers can seamlessly enable digital transformation within their ERP system combined with embedded analytics and are ready to lead the way in a highly competitive environment.

The powerful combination of all these advanced technologies offers a scalable and comprehensive solution for analysing the vast amounts of data generated in today’s digital manufacturing environments.

By harnessing these powerful insights, manufacturers can not only navigate the complexities of their own manufacturing sector but also seize opportunities for growth, innovation and competitive advantage. The age of embedded analytics in manufacturing is not just an overly hyped trend, but it is the foundation for the future of manufacturing excellence.