A team of agricultural and biological engineers from Penn State is working on a sustainable resin material made from agriculturally derived components, which has the potential to replace plastics currently used in large-format 3D printing for creating objects such as furniture and boats.

To support their research, the team has secured a $650,000 grant from the US Department of Agriculture’s National Institute of Food and Agriculture.

The researchers aim to create an alternative to existing, costly, and highly engineered resin materials that are derived from petrochemical sources, the university said in a news release.

The team, led by Stephen Chmely, an assistant professor of agricultural and biological engineering, is working on a renewable resin material made up of agriculturally sourced components.

“Our project team’s long-term goal is to develop new and sustainable bioproducts from lignocellulosic biomass — or dry plant matter — that economically enable a low-carbon bioeconomy,” Chmely said.

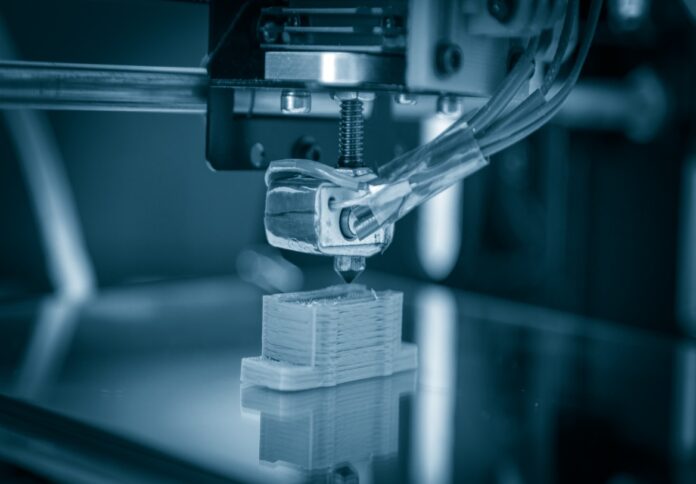

This material will enable large-format 3D printing using a technique called stereolithography, which constructs 3D objects layer by layer from a liquid polymer that solidifies when exposed to a laser beam.

The researchers are focused on creating chemical transformations of plant-derived materials, particularly lignin and nanocellulose, to develop stereolithography resins that incorporate these biomaterials along with soybean oil.

Lignin is a complex organic polymer found in plant cell walls, providing rigidity. Nanocellulose, composed of tiny particles typically derived from wood pulp, possesses unique properties that extend its applications.

According to Chmely, the team hopes that their new resins will exhibit improved elasticity, toughness, and thermal resistance compared to existing commercial resins.

They will assess these materials using spectroscopic and microscopic investigations, mechanical testing, and thermal analysis.

The interdisciplinary approach of this research, combining materials science and engineering with agriculture and forestry, leverages Penn State’s expertise in these areas.

“Our team has abundant expertise in lignin chemistry, cellulose nanomaterials and 3D printing by stereolithography,” Chmely said.

Jeffrey Catchmark, a professor of agricultural and biological engineering and bioethics, serves as a co-principal investigator on this project.