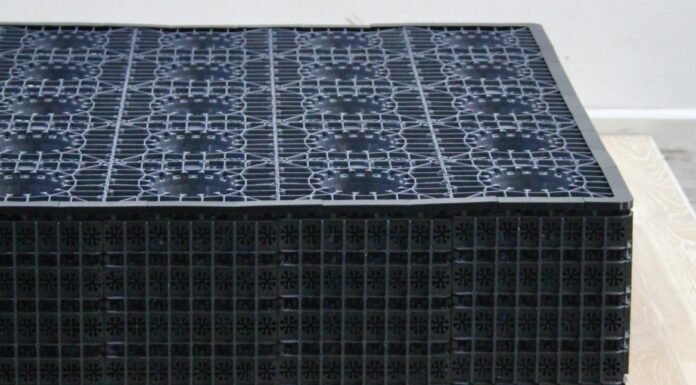

ASX-listed 3D printing company Aurora Labs has finalised the design of its AL250 printer, which is now entering the first stage of the physical assembly.

In an ASX announcement, Aurora Labs said it is now prepping the AL250 printer for incorporation into the machine frame for testing and validation.

The printer is designed to enable the bidirectional recoating of powders integrated with Aurora Labs’ MCP technology. This feature is intended to improve laser on-time, further increasing the duty cycle and efficiencies of the printing system.

The new 3D printing solution will also support research into the further development of MCP functionality in laser power bed fusion technology.

“This physical printer build culminates from months of detailed design work materialising into the first machine which will be our premier flagship printer model,” said Aurora Labs CEO Rebekah Letheby.

“Our design is built on the deep knowledge and expertise in laser powder bed fusion technology. It is great to see a high-quality, precision machine being built with Australian engineering at its core. The AL250 will be the best-in-class printer with robustness and reliability for its industrial users.”

Aurora is set to participate in the upcoming Indo-Pacific 2023 International Maritime Exposition as part of the Defence West delegation.

The company said AL250 will be promoted heavily in this field where the printer can provide the benefits of high productivity, enhance part performance through generative design freedom, and reduce component numbers with simplified geometries being able to be printed.

The first AL250 printer will support A3D’s AM services business and progress prospective machine buyers through a sales pipeline, with users able to assess the printer before acquisition.

Letheby said Aurora has developed novel features useful for material research, such as dynamic adjustment of layer height, and a proprietary powder dosing mechanism, which conditions the powder prior to delivery.

“This mechanism also moves non-spherical shaped powder which opens to industry a world of material development which includes the ability to lase inexpensive crushed or non-spherical powders, many which remain unexplored in laser powder bed fusion.”