North Carolina State University researchers have created a highly electrically conductive metallic gel that may be used to 3D-print solid structures at ambient temperature.

In the paper, titled, “Metallic Gels for Conductive 3D and 4D Printing,” the researchers revealed that the resulting gel may be produced with a standard 3D printing nozzle and preserves its shape after printing.

“3D printing has revolutionised manufacturing, but we’re not aware of previous technologies that allowed you to print 3D metal objects at room temperature in a single step,” said Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University.

He added, “This opens the door to manufacturing a wide range of electronic components and devices.”

To create the metallic gel, the researchers begin by making a solution of micron-scale copper particles suspended in water.

After that, the researchers added a little amount of an indium-gallium alloy, which is a liquid metal at normal temperature.

The resulting mixture is then combined, and the liquid metal and copper particles basically adhere to each other as the mixture is swirled, generating a metallic gel ‘network’ within the aqueous solution.

“This gel-like consistency is important because it means you have a fairly uniform distribution of copper particles throughout the material,” Dickey explained.

He continued, “This does two things. First, it means the network of particles connect to form electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.”

The resulting 3D object becomes even more solid while maintaining its shape when allowed to dry at normal temperature.

However, researchers said that some intriguing things can happen if users choose to apply heat to the printed object while it is drying.

The researchers discovered that the particle alignment affects how the material dries.

For instance, if one printed a cylinder, the sides would shrink more as it dried than the top and botto, and when drying occurs at room temperature, the process is slow enough to prevent structural changes in the object.

However, quick drying might result in structural deformation if heat is applied, such as by placing it under a heat lamp set at 80 degrees Celsius.

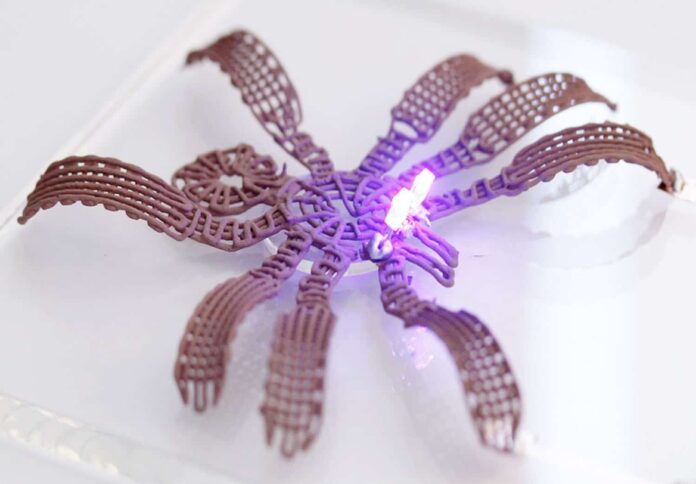

This predictable deformation means that by adjusting the printed object’s pattern and the quantity of heat it is subjected to during drying, you may modify the shape of the printed object after it has been made.

“Ultimately, this sort of four-dimensional printing – the traditional three dimensions, plus time – is one more tool that can be used to create structures with the desired dimensions,” Dickey stated.

He said that the team is willing to collaborate with business partners to investigate potential applications and that they welcome the chance to speak with new research partners.