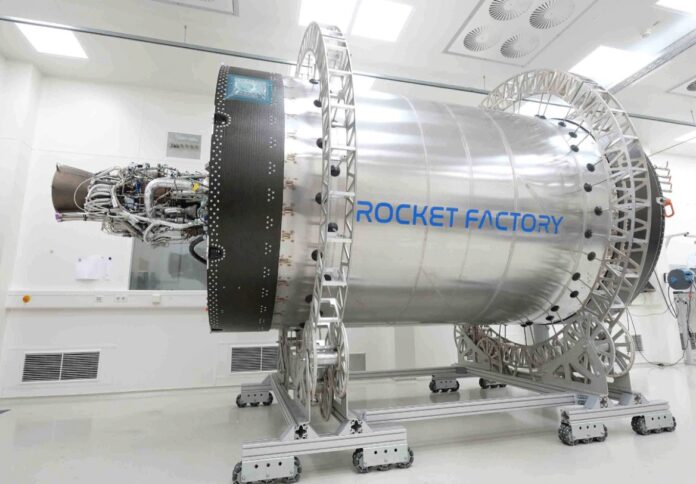

Australian 3D-printed heat exchanger manufacturer Conflux Technology is partnering with Rocket Factory Augsburg to develop aerospace heat exchangers as part of the Australian Space Agency’s Moon to Mars Initiative.

The AUD 1 million grant funding will be utilised to develop and produce the heat exchanger using 3D printing, the company said in a press release.

The heat exchanger will be created, produced, and functionally tested on the EOS M300-4 this year, and will be printed in Monel 500K material.

Dan Woodford, chief commercial officer at Conflux, said the company is establishing ourselves as a leader in the development and commercialisation of 3D-printed thermal solutions and relevant materials for extreme applications.

“With support from the Australian Space Agency’s Moon to Mars Grant Supply Chain Capability Improvement grant, we are now applying it to the rapidly expanding space industry,” Woodford remarked.

The Australian Space Agency’s Moon to Mars Initiative includes the Supply Chain Capability Improvement Grant Program.

The initiative assists Australian organisations with initiatives that could help the National Aeronautics and Space Administration’s (NASA) inspiring mission to go to the Moon and Mars.

This effort is also critical to the agency’s mission of transforming and growing the Australian space sector.

Conflux Technology said its additive-manufactured micro-structures and internal geometries permit exacting control of the ratio of the surface area presented to each fluid to maximise heat transfer and optimise turbulence and pressure drop.

Founded in 2018, Rocket Factory Augsburg (RFA) said its goal is to offer launch services of up to 1.300kg into low Earth orbits and beyond on a weekly basis at unmatched prices.