ASX-listed Australian Vanadium Limited said it has completed the detailed design, ordered long lead items and secured a site for its high-purity vanadium electrolyte manufacturing facility in Western Australia.

The electrolyte manufacturing technology of U.S. Vanadium LLC (USV) will be used, reducing the risk of construction and startup, the company said in a press release.

The Western Australia-based company said the facility will be capable of manufacturing a high-purity electrolyte for vanadium redox flow batteries (VRFB) up to 33MWh annually.

The expanding Australian long-duration energy storage sector, in which VRFBs will play a crucial part, will see AVL as an early mover in the provision of high-purity vanadium electrolyte.

AVL CEO Graham Arvidson expressed his delight to have acquired a site for the establishment of its first high-purity vanadium electrolyte manufacturing hub.

‘With detailed design now complete and long lead equipment ordered, we are positioned to become a near term producer,” Arvidson noted.

“This is an important step in our journey to become a world-class, vertically integrated “pit to battery” vanadium producer. By leveraging USV’s proven technology we have confidence in successfully realising our goal of producing the highest quality electrolyte available to the Australian and New Zealand VRFB markets,” he continued.

Meanwhile, Arvidson revealed that the company intends to investigate opportunities to replicate this electrolyte facility on Australia’s east coast in order to supply additional electrolytes for VRFB projects planned for deployment in a number of states and territories.

A $3.69 million grant from the Federal Government was given to AVL in 2021. 2 A portion of the money will be used to construct and run a commercial vanadium electrolyte manufacturing plant in Western Australia to aid in the commercialisation of VRFBs.

AVL said it is the exclusive licensee of USV’s process technology for the manufacture of vanadium electrolytes in Australia and New Zealand.

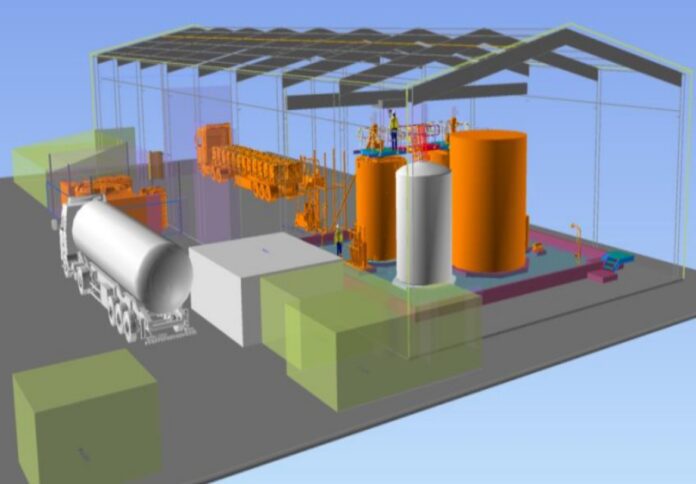

This technology was used in the design of the vanadium electrolyte manufacturing facility that will be built in Wangara, a northern Perth suburb.

Vanadium oxide feedstock for the electrolyte facility will be sourced through AVL’s agreement with USV until the production of vanadium oxides from AVL’s Midwest Processing Hub begins.

The construction and subsequent operation of the vanadium electrolyte facility will allow AVL to gradually mature its business processes, people, and systems in project execution and operations, the company revealed.

All long lead equipment items for the electrolyte facility have been ordered, with deliveries scheduled for the second quarter of 2023, and necessary statutory approvals are being sought.

In anticipation of the arrival and assembly of the electrolyte manufacturing equipment, site preparation work at the Wangara facility is expected to begin in April.