Media Release by AIM3D

Every 3D printing process competes with classic manufacturing strategies such as casting or milling in terms of mechanical properties, time factors and cost-effectiveness.

It is also in competition with alternative 3D printing technologies. The technological challenge: at present, layer-based 3D build processes of polymers often exhibit inhomogeneous structural properties.

With the patent-pending Voxelfill process, AIM3D is breaking new ground that overcomes inhomogeneous strength issues by achieving defined, selective densities in the component.

At Formnext 2022 and K 2022, two major autumn trade fairs in 2022, AIM3D will be providing information on two major highlights. On the one hand, the new Voxelfill process for sustainably improving the strength properties of a layer-based 3D component and, on the other hand, the market launch of the ExAM 510. This system complements the ExAM 255 by having a greater build area for large component volumes and will be shown in action at the trade fairs.

Voxelfill principle overcomes inhomogeneous strength properties

In additive manufacturing of polymers, components have inhomogeneous strength properties ??due to the layer-based build process. This manifests itself primarily in the form of tensile and flexural strength shortcomings, as well as very brittle behaviour along the Z axis. In contrast, the strengths achieved along the X and Y axes with some processes are already close to the strengths possible with conventional injection moulding. AIM3D has already demonstrated this with the processing of fibre-filled components based on PA6 GF30 material. The phenomenon of inhomogeneous strength properties must be resolved in order to enable a wide applicability of 3D-printed components. By using the 3D extrusion technology of the CEM process, AIM3D has developed a Voxelfill strategy that overcomes these limitations and increases the cost-effectiveness of the CEM process. Voxelfill can also be used for multi-material components and is suitable for constructing 3D components using plastics, metals and ceramics.

The two-stage Voxelfill process at a glance

With the Voxelfill approach, components are no longer created exclusively in layers (i.e. 2.5D), but utilise cross-layer filling by using so-called voxels as volume areas. To do this, , the component contour is first created as usual as the basic structure using one or more webs of the extruded material. A lattice pattern is created inside the component, which defines the boundaries of the volume elements to be filled, similar to cavities. This structure of the voxels to be filled resembles the honeycomb in a beehive. The Voxelfill strategy now comprises two process stages: 1. Generation of a lattice structure: the CEM system repeats this structure up to a defined height of the volume elements, then at this point the previously created cavities (voxels) are filled by injecting thermoplastic material with the extruder. 2. Filling phase of the voxels: now the second, even more important component of this 3D printing strategy is deployed: when the volume areas are filled, this does not include filling all voxels in one plane. This would again result in a Z-direction weakness directly in the “seam” plane. By shifting the volume elements halfway up the voxel, a kind of “brick-like bond” is created in the component, resulting in the yield line being offset. This results in an enormous increase in strength and also improves the elasticity of the components in the Z direction. In addition, the introduced volume elements greatly reduce the printing time for fully filled components and thus significantly increases the cost-effectiveness of the CEM process.

A look at the potential of Voxelfill

Variations of the Voxelfill strategy with the CEM process enable the use of various materials: hybrid multi-material solutions with different Voxelfill materials and different materials for the contour/structure of the inner walls become possible. This way, the material properties can be “customised”. Defined component weight, damping properties, elasticity or changes to the centre of gravity can be tailored to the application. By selectively filling only certain volume chambers (selective densities), component properties could be influenced in a targeted manner on the basis of FE simulations. With Voxelfill it is possible to only fill the areas of a component that are absolutely necessary for the flow of forces. As a result, from the outside these components purely look like conventional parts, and can also benefit from applying finishing processes. At the same time, however, the 3D printing process is carried out with reduced material and weight, right up to realising lightweight components. Especially when deploying fibre-reinforced materials, the use of Voxelfill offers an additional option for specifically aligning the fibres in the component to enhance mechanical properties. In the flat plane, the CEM process already offers very good options for controlling the orientation of the fibres. With the Voxelfill strategy, this affects the contour and the inner walls of the component. By injecting the material into the volume chambers (filling the voxels), the 3D component also receives fibres that are aligned in the Z axis, thereby further improving mechanical properties. Clemens Lieberwirth, CTO at AIM3D: “Of course, the Voxelfill process is particularly suitable for 3D printing of plastics and fibre-filled plastics, but it is also suitable for 3D printing of metal and ceramic components using the CEM process. In general, there are advantages due to the higher build speed and cross-layer filling.”

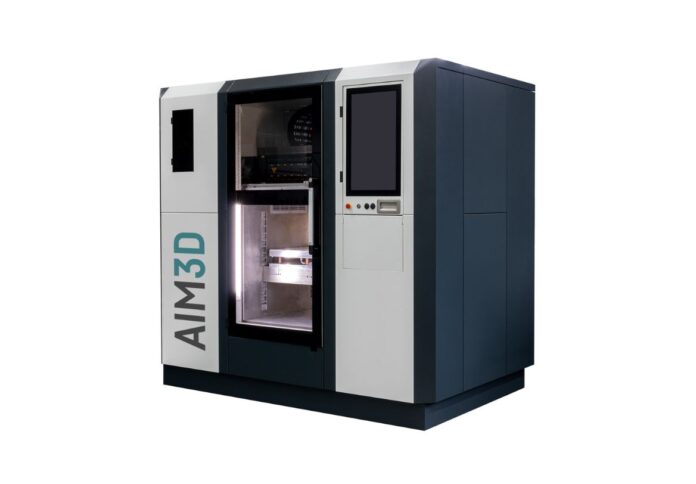

Launch of the ExAM 510

K 2022 and Formnext 2022 in the autumn of 2022 will mark the launch of AIM3D’s new ExAM 510 granulate printer. The Rostock-based company has developed this large CEM system up to the beta phase in a period of just 1.5 years. Beta phase users include ZF Friedrichshafen, Schaeffler and the Clausthal University of Technology. The new ExAM 510 offers a greater build area, higher precision and accelerated build speeds. The ExAM 510 printer is a multi-material printer for additive manufacturing that can consecutively print up to three materials. The increased build area of 510 x 510 x 400 mm³ now opens up a multitude of applications. The build area can be heated up to 200 ºC in order to reduce the stresses in the component and to process high-performance materials. The significantly increased build rate or print speed depends of course on the material used and can be as high as 250 cm³/h (when using a 0.4 mm nozzle). This extruder class enables extrusion rates that are up to 10 times higher than commercially available filament extruders. The special appeal of the ExAM 510 is revealed by the materials that can be deployed. AIM3D has equipped the system with a heatable process chamber specially designed for the use of high-temperature plastics. This makes it possible to also process high-temperature plastics such as PEEK, PEI, PSU, PPS, with or without fibre filling.