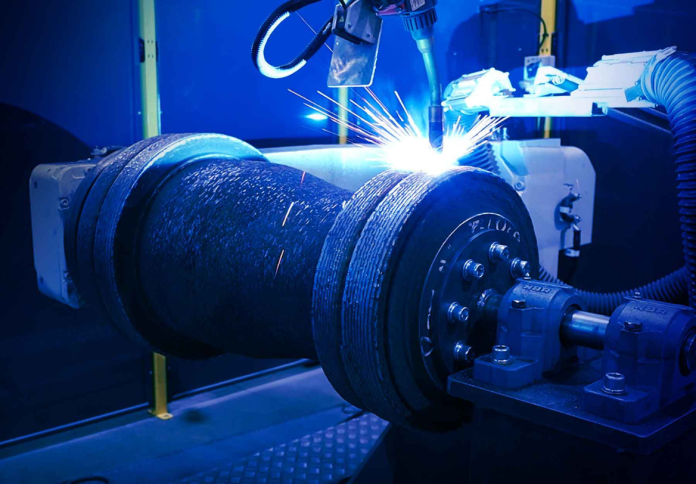

Wire additive manufacturing (WAM) company AML3D has received the first-ever Additive Manufacturing Facility accreditation from DNV, a leading global marine & industrial classification society.

In a media statement, AML3D said the recognition reflects WAM technology’s compliance with class certification standards for integrity and quality, which are required for components designed for the oil and gas and marine industry.

According to AML3D, the status gives it a significant competitive advantage as the only wire-feed additive manufacturer accredited to supply high-value parts— designed to operate in extreme load, pressure, or corrosive environments— to DNV’s customer base around the world.

The accreditation encompasses an “Approval of Manufacturer” certificate, which will also boost AML3D’s growth strategy aimed at increasing sales of existing products, entering new markets, and expanding its potential customer base.

Additionally, the DNV recognition also extends the range of contracts and customers AML3D can target in maritime, oil and gas and Navy/Defence Marine organisations.

“DNV offers a broad range of customers including a heavy focus on Oil & Gas sector, a key growth target for AML3D,” said Andrew Sales, managing director of AML3D.

“This accreditation is a game changer for us, in terms of the ability to issue Class Certificates using our WAM process. We’re very excited to have a great relationship with DNV and explore opportunities amongst their customer base,” he added.

The latest accreditation follows AML3D’s recent announcement for the implementation of the AS9100D:2016 Standard for aerospace components and a previous world-first wire-arc additive manufacturing facility certification by Lloyd’s Register.

The combined customer base of DNV and Lloyd’s Register gives AML3D access to two-thirds of the global market for high-value, class-certified marine components, according to the WAM developer’s estimation.