ABB’s reduced VOC painting systems have set new industry benchmarks for product performance and low environmental impact.

Image credit: flickr.com

User:ABBgroupmediarelations

An article featured on ABB’s website reveals that the company has used reduced VOC paints on power and distribution transformers for more than a decade. According to ABB, the results are quite good.

Conventional paints contain color pigments and binding agents. These components are suspended in an organic solvent to get the right consistency. As the paint dries the solvent evaporates, thus dispersing VOCs or volatile organic compounds into the air.

Airborne VOCs react with other pollutants and sunlight to form ground-level ozone and smog, which are harmful to health and the environment.

In order to find a solution for this problem, ABB Transformers launched an initiative in 2011 aimed at reducing VOC emissions in its painting processes. The goal was to replace the solvent-based paint applied on transformer tanks with the more environmentally friendly paints that are water-based and high solid.

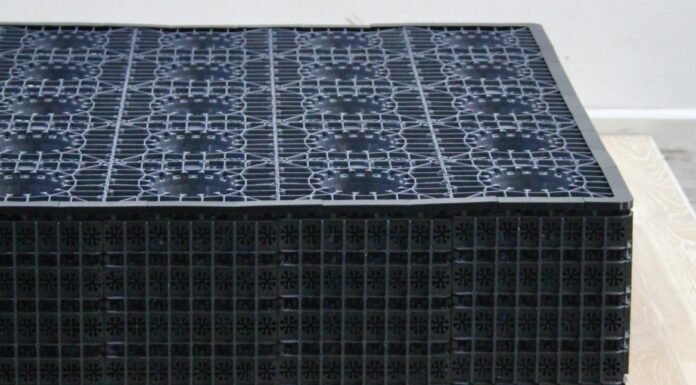

Since ABB is a world leading manufacturer of transformer products, this step was quite crucial. Their products are frequently subjected to punishing indoor and outdoor environments and a lot of paint is needed to protect them- and lots of paint means lots of VOC emissions.

Any new painting process had to significantly reduce VOC emissions without compromising the quality and reliability of their products.

ABB`s low-VOC painting processes are associated to a system of specifications based on IEEE and ISO international standards.

The goal is to reduce the company’s VOC emissions by 294 metric tonnes, equivalent to the yearly VOC emissions of approximately 25,000 average sized cars.

According to the company, this new system works in exactly the same way as conventional paint systems. The only difference is the amount of solvent in the paint, which is either reduced or completely eliminated.

Low-VOC processes are setting new paint operation standards for the company, as well as the supply chain for outsourced painted parts, where ABB has already introduced approved, standardized low-VOC painting systems to suppliers.

ABB manufacturing units are also reporting better paint quality and improved work environments.

This shift to environmentally friendly painting systems does not in any way compromise the performance or durability of paint coatings and finishes. The company also claims that there is also no additional impact on costs.