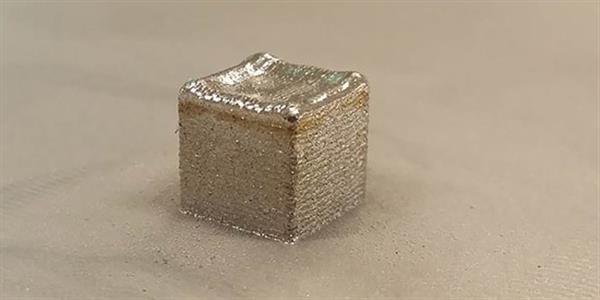

Researchers at the Institute for Frontier Materials have successfully 3D printed a Boron Nitride Nanotube/Titanium (BNNT)composite in a move that could have significant implications for industries such as aerospace, defence, automotive, energy and health.

Alfred Deakin Professor Ying (Ian) Chen, Chair in Nanotechnology at Deakin University said this ‘novel and scalable’ manufacturing process will allow the production of BNNTs in large quantities for the first time since the material was first discovered two decades ago.

“Boron Nitride Nanotubes are an advanced new nanomaterial with many unique properties. They are ultralight, super strong and incredibly resistant to heat,” Mr Chen said.

“However, in the 20 years since the material’s discovery, it has only been possible to produce in small amounts. This has seriously limited its practical use in product development.”

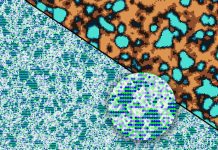

BNNTs are similar in structure to carbon nanotubes and both materials share the same extraordinary mechanical properties and thermal conductivity.

However, BNNTs are able to withstand double the temperatures (up to 800° C), have greater chemical stability and electrical insulation properties, and are able to shield against neutron and ultraviolet radiation and to generate electrical current when subjected to mechanical stress.

Professor Chen said the superior heat tolerance is critical for surviving the extreme temperatures involved in melting and liquefying powders during the 3D printing process for metal matrix composites.

“When integrated into composite materials and systems, BNNTs enable entirely new classes of material performance across many industrial applications,” he added.

According to him, the material can be used for the production of metallic, polymer and ceramic composites and transparent materials for the defence and the automotive sector; thermally conductive and electrically insulating material for the semiconductor industry and sensors and structural or multifunctional applications for the aerospace and energy sectors.

Additionally, BNNTs can be used in batteries, supercapacitors and hydrogen storage devices for energy storage, fire retardant construction materials for the construction sector and cancer and cellular regeneration therapies.

Mr Chen said the ability to realise this potential commercially had been restricted by the costly and energy intensive production processes that had been used to date.

“In contrast, the Deakin BNNT technology promises to offer the highest production rate as well as being more energy efficient and industry friendly, as it is based on current industry equipment,” Professor Chen continued.

“It has been demonstrated at laboratory scale at Deakin and has been running as needed to produce enough BNNTs for both internal and external research purposes, including several different products such as BN nanotube films, coatings and buckypapers, which are not available elsewhere. BN buckypapers could be used in aircraft as a radiation shielding layer, as filters for removing contaminants from water, and to make lightweight and stronger vehicles and aircraft.”

Deakin has already patented its BNNT production technology and plans to build a commercial BNNT pilot plant at its Waurn Ponds campus to produce BNNTs in kilogram quantities.