V2 Group and Caracol AM have developed the first functional large-format 3D-printed monolithic catamaran, a six-meter vessel built with robotic 3D printing technology to advance the scalability of 3D-printed boats.

According to V2 Group and Caracol AM, the project integrates design, materials, production, and post-processing techniques tailored to the requirements of the naval industry.

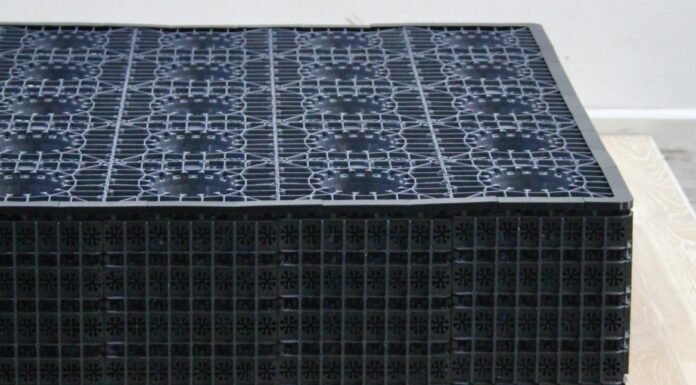

They state that large-format 3D printing offers advantages such as customisable designs, efficient material usage, and reduced environmental impact.

The technology enables faster production times, minimises waste, and supports the creation of high-quality floating structures that align with market demands, V2 Group said in a news release.

A key focus of the initiative has been to explore the feasibility of scaling up production while ensuring sustainability and economic viability.

From selecting suitable materials to optimising printing times and assembly processes, the project has reportedly laid the groundwork for broader adoption of this manufacturing approach within the nautical sector.

Industry experts view this development as a potential shift in boat manufacturing. By demonstrating the feasibility of robotic 3D printing in constructing functional vessels, the project positions the technology as a viable alternative to traditional methods.

The partnership between V2 Group and Caracol AM highlights ongoing efforts to develop innovative solutions for naval applications, with the aim of integrating large-scale 3D-printed boats into mainstream production.

The companies state that continued refinement of the process will be crucial for wider adoption, with industrialisation efforts paving the way for a more scalable and sustainable production model.