3D People, a provider of high-quality, on-demand 3D printed parts, has expanded its service offerings by adding Ultrasint TPU01, a new flexible elastomeric material optimised for HP’s MultiJet Fusion (MJF) additive manufacturing (AM) system.

Felix Manley, co-founder of 3D People, highlighted the benefits of the new material: “Flexibility is the key to the TPU01 material, and in more than one way. The material itself is the most advanced elastomeric material developed for the MJF AM system from HP, and as a result, it produces the highest quality, flexible parts”

He continued, “Introducing this material also provides more flexibility for our customers, a significant number of whom have been asking for it.”

3D People’s technicians bring specialised expertise to their MJF technology operations, having completed HP’s comprehensive “Train to Maintain” program, which ensures optimised performance and high-quality results.

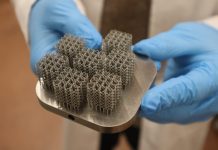

The TPU01 material’s unique properties make it particularly suited to AM processes, and according to Sasha Bruml, 3D People’s co-founder, the material allows for the production of highly complex geometries, including customisable lattice structures.

“Combine that capability with this material, and we are able to offer a distinct advantage for our customers who are looking to fine-tune the hardness, flexibility, and shock absorption of their applications,” Bruml explained.

A notable feature of the TPU01 material is its compatibility with vapour smoothing processes, which allows 3D People to deliver products with enhanced finishes.

Unlike many elastomeric materials used in additive manufacturing that struggle to achieve smooth surfaces, TPU01 undergoes vapour smoothing to increase water tightness and reduce the risk of crack formation.

This property brings TPU01 parts closer in performance to traditionally moulded polyurethane parts, which have long been a standard for durability in many industries.

The cost-efficiency of the MJF process also makes TPU01 a competitive choice for clients, particularly for batch production.

With TPU01 parts available at pricing comparable to PA12 MJF parts, 3D People’s customers can achieve cost-effective solutions without sacrificing quality or turnaround time.

To meet growing demand, 3D People has dedicated a specialised schedule on its MJF machines specifically for TPU01 production, allowing for rapid and reliable delivery of flexible parts.

This new addition, along with a set of design guidelines developed by the company’s experts, enables customers to optimize TPU01’s unique properties in applications ranging from shock absorption to aesthetic finisheS.