Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) are developing a ‘one-stop shop’ system to print functional, custom-made devices and robots, without human intervention.

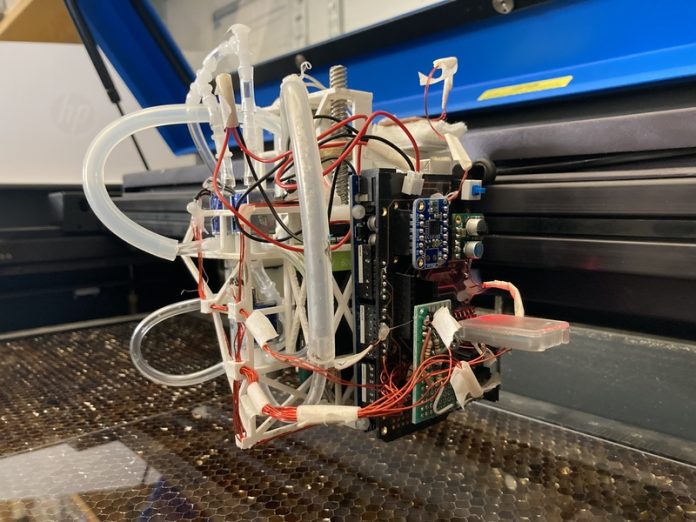

Called “LaserFactory”, the system uses a three-ingredient recipe that lets users create structural geometry, print traces, and assemble electronic components like sensors and actuators.

It features two parts that work in harmony: a software toolkit that allows users to design custom devices, and a hardware platform that fabricates them.

CSAIL PhD student Martin Nisser said LaserFactory could prove to be beneficial for product developers, makers, researchers, and educators looking to rapidly prototype things like wearables, robots, and printed electronics.

“Making fabrication inexpensive, fast, and accessible to a layman remains a challenge,” Nisser said.

“By leveraging widely available manufacturing platforms like 3D printers and laser cutters, LaserFactory is the first system that integrates these capabilities and automates the full pipeline for making functional devices in one system.”

While 3D printers lack the ability to fabricate more complex devices that are essentially ready-to-go right out of the printer, LaserFactory automatically cuts the geometry, dispenses silver for circuit traces, picks and places components, and finally cures the silver to make the traces conductive, securing the components in place to complete fabrication.

Nisser and his fellow researchers, who are now fine-tuning the current system, hope to build on this technology by exploring how to create a fuller range of 3D geometries, potentially through integrating traditional 3D printing into the process.

“Beyond engineering, we’re also thinking about how this kind of one-stop shop for fabrication devices could be optimally integrated into today’s existing supply chains for manufacturing, and what challenges we may need to solve to allow for that to happen,” he continued.

“In the future, people shouldn’t be expected to have an engineering degree to build robots, any more than they should have a computer science degree to install software.”

Image credit: https://news.mit.edu/